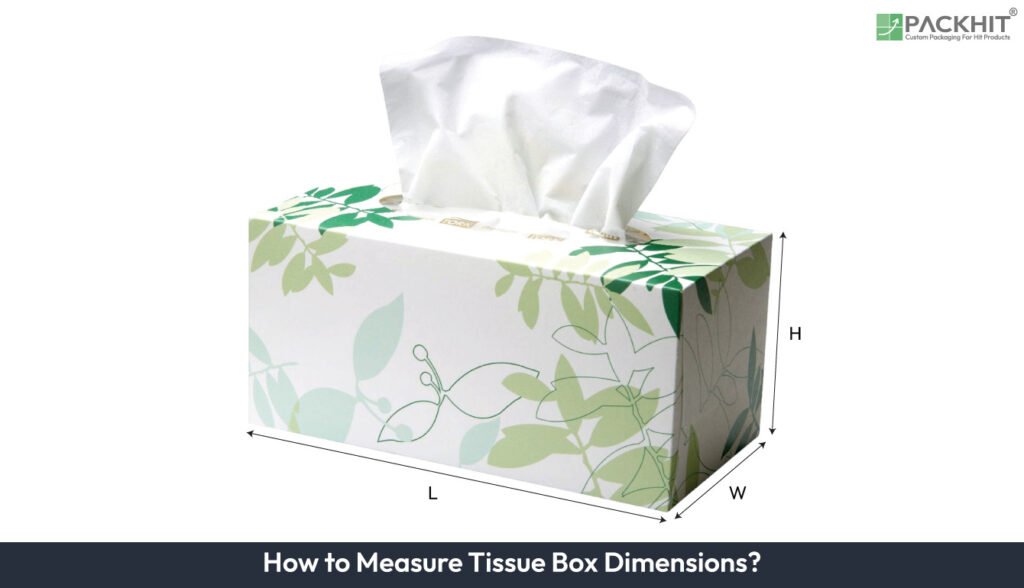

To measure a tissue box, place it on a flat surface and record its Length × Width × Height, noting both external and internal dimensions. Accurate measurements depend on box type, curvature across board faces, and board thickness. Use a flat surface, the proper tools, and take readings at multiple points to avoid errors. External dimensions show the outer frame, while internal dimensions indicate the usable inner space for tissues. Standard shapes like rectangular, cube, and shallow “slice” boxes follow simple formulas for volume, but irregular or cylindrical boxes require additional checks. Correct measurement ensures proper refill fit, consistent tissue pull and reduces issues during production and transport.

- What to Check Before Recording Tissue Box Dimensions?

- What are the Steps to Measure Tissue Box Dimensions?

- 1. Prepare the Tissue Box

- 2. Measure the Length

- 3. Measure the Width

- 4. Measure the Height

- 5. Measure the Opening (Optional)

- 6. Record the Measurements

- 7. Double-Check the Calculations

- How to Calculate the Volume of a Tissue Box?

- What are Standard Tissue Box Dimensions?

- Why Measure the Internal Dimensions of a Tissue Box?

- How to Measure a Shallow Tissue Box?

- Common Measurement Errors in Tissue Box Dimensions

- Tips for Accurate Measurement of Tissue Box Dimensions

What to Check Before Recording Tissue Box Dimensions?

Before recording tissue box dimensions, confirm each reading and set the baseline criteria through the following list:

- State units in mm and in to align drawings, cutter layouts, and refill‑stack checks across rectangular, cube, and slice bodies.

- List L × W × H for each style and add a bounding set for irregular shapes such as triangular or cylindrical packs.

- Mark each reading as external or internal to separate outer frame size from the usable inner clearance that controls stack fit.

- Record length, width, corner radii, and aperture offsets; each figure changes sheet pull and affects how shallow and slice boxes release the top sheet.

- Note the tool for each axis, such as a steel rule for short faces, a tape for spans above 150 mm, or a calliper for internal reaches in curved bodies.

- Add permitted deviation and inspection points that match pallet checks, and bend‑drift tolerances used during shipper setup.

What are the Steps to Measure Tissue Box Dimensions?

The steps to measure tissue box dimensions are as follows:

- Prepare the Tissue Box

- Measure the Length

- Measure the Width

- Measure the Height

- Measure the Opening (Optional)

- Record the Measurements

- Double-Check the Calculations

1. Prepare the Tissue Box

Prepare the tissue box by placing it on a flat surface and clearing the inner space. This action sets a clear measuring baseline and reduces height loss that appears when the bottom panels bend during stacking checks. Flat placement creates a stable baseline used to compare deformation between filled and empty units.

2. Measure the Length

Measure the length by recording the longest top reach from edge to edge. Keep the tape aligned with the true axis; angled contact adds measurable drift, often 1–2 mm in laminated cartons. Take a second reading along the opposite face to confirm the bends at one edge. This follow‑up check keeps the length aligned with the main axis and matches the step that follows, which records values in millimetres and inches. Record values in millimetres, centimetres, and inches.

3. Measure the Width

Measure the width by recording the shorter top reach at a right angle to the length. Set the tape across the flattest surface; moving into the corner radius reduces the usable reach by 2–4 mm in typical layouts. Record external width and internal width.

4. Measure the Height

Measure the height by recording the distance from the base to the highest point of the top board face. Use a firm surface to avoid compression. Repeat readings if the board face slopes or if a raised collar borders the opening. Small collar variations change internal depth, and internal depth controls sheet‑stack fit inside outer shipping cartons.

5. Measure the Opening (Optional)

Measure the opening by recording the aperture length, aperture width, and offsets from the top‑panel edges. Use a digital calliper to capture narrow and wide internal reaches and avoid pressing into the board, which distorts the reading. Add corner‑radius notes because a shift of 1–2 mm changes sheet tension and disrupts pull in shallow slice formats.

6. Record the Measurements

Record the measurements in L × W × H and label each figure as external or internal. UK specification sheets list values in this order to keep layout files clear and to reduce mix‑ups when tooling data changes. Add aperture length, aperture width, and their offsets in the same block if the box includes a top opening. Keep units consistent and note whether readings come from the flat panel edge or the inner clearance, because a 2–3 mm shift affects the usable inner space.

7. Double-Check the Calculations

Double‑check the calculations by repeating each axis and verifying the aperture reach. Confirm readings at two points if board faces bow. This check removes common errors such as diagonal tape pulls, mixed units, and unclear external–internal values. Consistency across both readings supports accurate inner‑space mapping and reduces print‑to‑cut drift during production.

How to Calculate the Volume of a Tissue Box?

Calculate the volume of a tissue box by multiplying its base area by its height. Use the external or internal dimensions based on whether you assess outer capacity or the usable inner space for the tissue stack. Most tissue packs follow simple geometry, such as:

- Rectangular and cube packs use length × width × height based on straight top‑panel reaches, if curled edges shorten the clear axis.

- Cylindrical packs use π × r² × height and record diameter at the midpoint, if the wall gauge changes internal space.

- Shallow slice boxes use the rectangular formula and confirm height on a flat surface, if the aperture frame reduces internal depth.

- Irregular bodies use a bounding length × width × height to estimate volume, if side contours compress one corner or shift the stack toward the opening.

What are Standard Tissue Box Dimensions?

Standard rectangular tissue boxes in the UK is 9.00 × 4.50 × 2.00 in (22.86 × 11.43 × 5.08 cm) or 228.6 × 114.3 × 50.8 mm. This table lists four common tissue‑box formats and presents their external L × W × H measurements in inches, centimetres, and millimetres.

| Style | Dimensions (inches) | Dimensions (cm) | Dimensions (mm) |

|---|---|---|---|

| Rectangular (household) | 9.00 × 4.50 × 2.00 in | 22.86 × 11.43 × 5.08 cm | 228.6 × 114.3 × 50.8 mm |

| Cube (tabletop) | 4.50 × 4.50 × 5.25 in | 11.43 × 11.43 × 13.34 cm | 114.3 × 114.3 × 133.4 mm |

| Travel / Pocket | ~4.25 × 3.50 × 0.90 in | ~10.8 × 8.9 × 2.3 cm | ~108 × 89 × 23 mm |

| Refill Pouch | Variable | Variable | Variable |

The table above groups four tissue-box formats and lists their external L × W × H dimensions across three matching unit sets. This comparison clarifies how each format occupies space and supports quick capacity checks during carton planning.

Why Measure the Internal Dimensions of a Tissue Box?

Internal dimensions show the usable inner space for the tissue stack and control sheet clearance, movement, and pull strength. These readings fix how the bundle sits inside the frame if coatings or board gauge tighten the fit. Internal dimensions also support transport checks because small gaps shift the stack during handling. Accurate readings prevent jams, reduce crushed edges, and ensure the opening matches the sheet height for smooth release.

How to Measure a Shallow Tissue Box?

Measure a shallow tissue box by recording its external frame, internal inner space, and opening geometry in one continuous sequence. The following steps below explain how to properly measure a shallow tissue box:

- Record the external frame across the top board face and capture length and width at true edges.

- Place the box on a flat surface so it doesn’t bend.

- Measure from bottom to top and subtract the board thickness on both sides.

- Measure the inside width (longest and narrowest) and include the top edge space.

- Even 1–2 mm change affects how the tissues pull out.

- Measure at two points on each side because thin boxes can bend when stacked.

How to Measure Irregular Tissue Box Shapes?

To measure irregular boxes, first set a bounding L × W × H. Depending on the shape, take specific measurements for triangular, cylindrical, or novelty boxes, such as:

- Triangular bodies: record base width, side lengths, peak height, and aperture reach for narrow and wide points.

- Cylindrical bodies: record diameter and height, confirm roundness at two angles, and mark aperture centre offsets.

- Novelty contours: record the bounding rectangle, note the contour that restricts clearance, and add any flared top reach.

Common Measurement Errors in Tissue Box Dimensions

Common measurement errors in tissue box dimensions are as follows:

- Diagonal measurement: Diagonal checks stretch the reading across two edges and give a longer figure than the real edge‑to‑edge reach. This error appears often in rectangular, cube, and shallow slice boxes, and it shifts the layout size during carton setup.

- Unit omission: Missing mm or in creates mixed records in packing rooms that use both units for refill and tabletop checks. Dual‑unit sheets from recent tissue‑box guides show that a missing unit changes cutter settings and confuses planning teams.

- Ignoring aperture: Skipped opening readings hide changes in aperture width, aperture length, and corner radius. Slice boxes use these figures to control pull strength, and even a 1–2 mm shift creates extra drag across the top sheet.

- Single‑point checks: One reading on a bowed face hides the real tolerance range. Three checks across each face show drift that appears in many household packs, if the board bends during pallet stacking.

- Unrecorded board thickness: Missing board gauge removes the correction gap between outside and inside measurements. This gap fixes the planned inner space for refill packs and keeps the tissue stack from compressing against the side walls.

- Internal/external confusion: Unclear labels mix the inner space with the outside frame. This mistake changes how the tissue stack sits inside the box, if the board gauge tightens the internal gap during production.

Tips for Accurate Measurement of Tissue Box Dimensions

Accurate measurement depends on clear axis control, stable placement, and repeat checks across the box faces. The key points below group the essential tips used during practical measurement such as:

- Use a steel rule for short external faces, a tape for readings above 150 mm, and a calliper for internal readings.

- Place the tape on the true edge; corner drift inflates readings.

- Record inch and millimetre values in the same entry if dual reporting applies.

- Measure both sides of each axis to detect curl or bow.

- Use a firm surface to avoid height compression.

- Capture widest and narrowest aperture reach and record offsets.

- Measure board thickness to refine internal figures.

- Check edges under direct light to show warps.