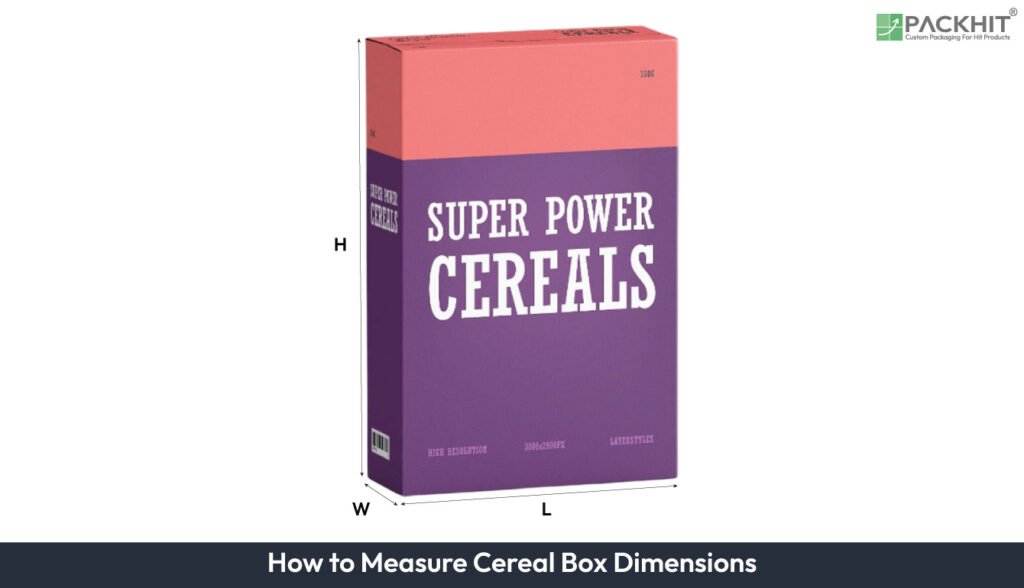

To measure cereal box dimensions, record length (L) × width (W) × height (H) as three separate axis readings taken from a closed carton placed on a flat surface. Use measuring tapes, metal rulers, callipers, and set squares to capture crease‑to‑crease values across the panels. Start with an empty, closed box so the panels sit flat and the height remains steady. Record the longest horizontal edge as length (L), the shorter horizontal edge as width (W), and the vertical edge as height (depth). Measure internal dimensions directly, or subtract board thickness from each external axis if the board maintains the same calliper across all panels. Cereal boxes fall into four size categories used across retail channels, such as standard retail, compact or mini formats, family or bulk packs, and extra‑large promotional runs. Accurate readings support volume calculations, shelf clearance, pack format comparisons, dieline geometry, stacking patterns, and transport checks. Frequent errors include axis confusion, bent or warped panels, open flaps, and mixed unit sets; these typically appear in packaging audits when panel strain or humidity shifts distort readings. Improve precision by checking panel flatness, measuring along the same axis each time, keeping the box closed during height readings, repeating each measurement, and writing the units next to every entry.

- What Tools are Used to Measure Cereal Box Dimensions?

- Steps to Measure the Cereal Box Dimensions

- 1. Preparation of the Cereal Box

- 2. Measure the Length

- 3. Measure the Width

- 4. Measure the Height (Depth)

- 5. Measure the Internal Dimensions

- 6. Record Final Numbers

- How to Calculate the Volume of the Cereal Box?

- Standard Cereal Box Dimensions in Inches, Millimetres, and Centimetres

- Why Accurate Cereal Box Dimensions Matter?

- Common Measurement Errors in Cereal Box Dimensions

- Tips for Precise Cereal Box Dimension Measurement

What Tools are Used to Measure Cereal Box Dimensions?

The tools used to measure cereal box dimensions include measuring tapes, metal rulers, callipers, and set squares. Each tool captures a specific axis or crease point, and the selection depends on panel length, board stiffness, and whether internal or external readings are needed.

Steps to Measure the Cereal Box Dimensions

To measure the dimensions of a cereal box, follow the steps below:

- Preparation of the Cereal Box

- Measure the Length

- Measure the Width

- Measure the Height (Depth)

- Measure the Internal Dimensions

- Record Final Numbers

1. Preparation of the Cereal Box

Remove the inside bag or loose flakes so the panels stay flat. Close the top and bottom flaps, press the folds until they sit tight, and place the box on a flat table so the sides stand straight and the edges do not tilt.

2. Measure the Length

Measure the longest horizontal edge on the front panel and record that number as length (L). Hold the tape tight against the surface and check the reading at eye level. Use the centre section of the panel for the reading, and repeat the step three times if the carton bends or twists.

3. Measure the Width

Measure the shorter horizontal edge that sits 90 degrees to the length and record that number as width (W). Add the unit after the number for clear reference.

4. Measure the Height (Depth)

Measure straight from the bottom edge to the top edge for height and from front to back for depth. Many retail plans use both values, so state which one you record. Keep the box closed so the top panel stays flat during measurement.

5. Measure the Internal Dimensions

Measure the inside cavity with a tape or callipers when you need the box’s usable space. If you only have the outside numbers, subtract twice the board thickness from each axis if the board thickness stays even. Direct readings from inside the box give the closest estimate of the product-fit area.

6. Record Final Numbers

Write the final numbers using the format you select, such as L × W × H, and list the unit next to each value. Note whether the carton was empty or filled, list any averaging step, and confirm if the sizes represent internal or external measures. Consistent notes avoid confusion during production checks.

How to Calculate the Volume of the Cereal Box?

Calculate volume by multiplying the external length, width, and height (L × W × H). This calculation gives the total capacity used for product fill and shelf planning. For example, a box that measures 12 in × 8 in × 2 in has a calculated volume of 192 cubic inches. This estimate shows how much space the product occupies inside the sealed carton.

Standard Cereal Box Dimensions in Inches, Millimetres, and Centimetres

Cereal boxes fall into four consistent retail size groups that reflect external panel ranges used for dielines, pallet counts, and shelf-fit assessments. The table summarises the common panel lengths, widths, and heights referenced across UK and US manufacturing channels.

| Category | Length (inches/mm/cm) | Width (inches/mm/cm) | Height (inches/mm/cm) |

|---|---|---|---|

| Standard retail (mid-range) | 12 in / 305 mm / 30.5 cm | 8 in / 203 mm / 20.3 cm | 2 in / 51 mm / 5.1 cm |

| Compact / Mini | 5–8 in / 127–203 mm / 12.7–20.3 cm | 3–5 in / 76–127 mm / 7.6–12.7 cm | 1–2 in / 25–51 mm / 2.5–5.1 cm |

| Family / Bulk | 14–18 in / 356–457 mm / 35.6–45.7 cm | 9–12 in / 229–305 mm / 22.9–30.5 cm | 3–4 in / 76–102 mm / 7.6–10.2 cm |

| Extra-large promotional | 18–20 in / 457–508 mm / 45.7–50.8 cm | 10–12 in / 254–305 mm / 25.4–30.5 cm | 3–5 in / 76–127 mm / 7.6–12.7 cm |

The ranges show how each format controls shelf height, presentation width, and fill depth, and how panel geometry sets predictable constraints for dielines and transport planning.

Why Accurate Cereal Box Dimensions Matter?

Accurate cereal box dimensions matter because they define the external size used to calculate volume, confirm shelf clearance, and set die-line geometry for manufacturing. These measurements guide carton layout, stacking patterns, pallet counts, and artwork placement. Size variation occurs because brands change panel size, depth, and height to match product mass and serving ranges.

Common Measurement Errors in Cereal Box Dimensions

Common measurement errors in cereal box dimensions are as follows:

- Axis confusion: Mislabelled length, width, or height creates reversed dielines. Examples include swapping the front‑panel length with the side‑panel width.

- Panel distortion: Warped cartons change crease‑to‑crease readings. Examples include bowed side walls from humidity shifts.

- Open-flap readings: Unsealed tops alter height. Examples include cartons with floating dust flaps during measurement.

- Inconsistent unit handling: Mixed inch–centimetre conversions cause mismatched values. Examples include double‑rounded millimetre entries.

- Averaging gaps: Single‑point readings hide local thickness changes. Examples include boards with uneven calliper near compression points.

Tips for Precise Cereal Box Dimension Measurement

To measure cereal box dimensions precisely, follow the tips below:

- Check panel flatness before measuring; bowed fibreboard. For example, humidity‑softened front panels, shift crease‑to‑crease values.

- Place the tape or ruler on the same axis each time; inconsistent start points. For example, top‑flap edges distort dimension logs.

- Hold the carton closed while measuring exterior height; loose dust flaps create 1–3 mm height variation.

- Repeat each axis at least twice; variation between readings. For example, a 1–2 mm spread indicates panel flex.

- Record the unit with each number; mixed inch–centimetre sets. For example, rounded conversions cause dieline errors.

What are the Standard Cereal Box Dimensions?

The standard cereal box in the UK uses external panels close to 30.5 cm × 20 .3 cm × 5 .1 cm.

Which Unit Should Be Used When Measuring Cereal Box Dimensions?

Use millimetres for cereal box dimensions because packaging dielines, crease‑to‑crease offsets, and board calliper data rely on mm increments. Millimetres capture small shifts, for example 1–2 mm panel drift, that affect folding accuracy. Manufacturers also record inches for retail checks, if buyers request US‑standard axis logs. Centimetres give quick consumer‑level references, if the carton format only needs rounded values.

Why Measure a Cereal Box When It’s Empty, Not Filled?

Measure an empty cereal box to record stable external dimensions used for dielines, pallet plans, and shelf checks. A filled carton expands under product weight, and that expansion shifts height, width, and front‑panel length by 1–3 mm. Empty‑box readings reflect the panel geometry that manufacturers specify in production logs. Measure filled cartons only for front‑facing checks or shelf‑edge visibility tests.

How to Translate Cereal Box Dimensions into a Dieline?

Convert folded external dimensions into panel widths and add glue/overlap and bleed allowances for the flat layout. Specify whether dimensions are final folded size or panel extents; include material thickness so that panel widths account for board calliper and scoring positions.