Foil stamping delivers premium visual effects and tactile appeal that elevate packaging and strengthen brand perception. The process of foil stamping uses heat, pressure, and metal dies to transfer foil onto substrates, while different stamping methods and foil types support varied design and production needs. The flexibility across processes, types, and substrates helps balance aesthetic impact, functional performance, and cost efficiency while addressing operational and environmental considerations. Widely applied in luxury, promotional, and secure packaging, foil stamping continues to evolve with technological advances, offering creative possibilities for high-quality, attention-grabbing packaging solutions.

- What is Foil Stamping?

- What is the Importance of Foil Stamping in Packaging?

- How Does the Foil Stamping Process Work in Packaging?

- Step 1: Prepare the Stamping Die

- Step 2: Position the Foil

- Step 3: Press and Transfer the Foil

- Step 4: Inspect and Finish

- What are the Types of Foil Stamping Used in Packaging?

- 1. Hot Foil Stamping

- 2. Cold Foil Stamping

- 3. Digital and Transfer Foiling

- What are the Components and Finishes of Foil Used in Packaging?

- What are the Tooling Types Used in Foil Stamping?

- What are the Benefits of Foil Stamping in Packaging?

- Enhanced Visual Appeal

- Elevated Tactile Experience

- Strengthened Security

- Improved Production Compatibility

- Targeted Material Efficiency

- Optimised Cost Performance

- How do Production Factors Influence Foil Stamping Costs?

- What are the Environmental and Recycling Considerations for Foil Stamping?

- What are the Key Applications of Foil Stamping Across Industries?

- What are the Challenges of Foil Stamping in Packaging?

- How to Select the Right Foil Stamping Method?

What is Foil Stamping?

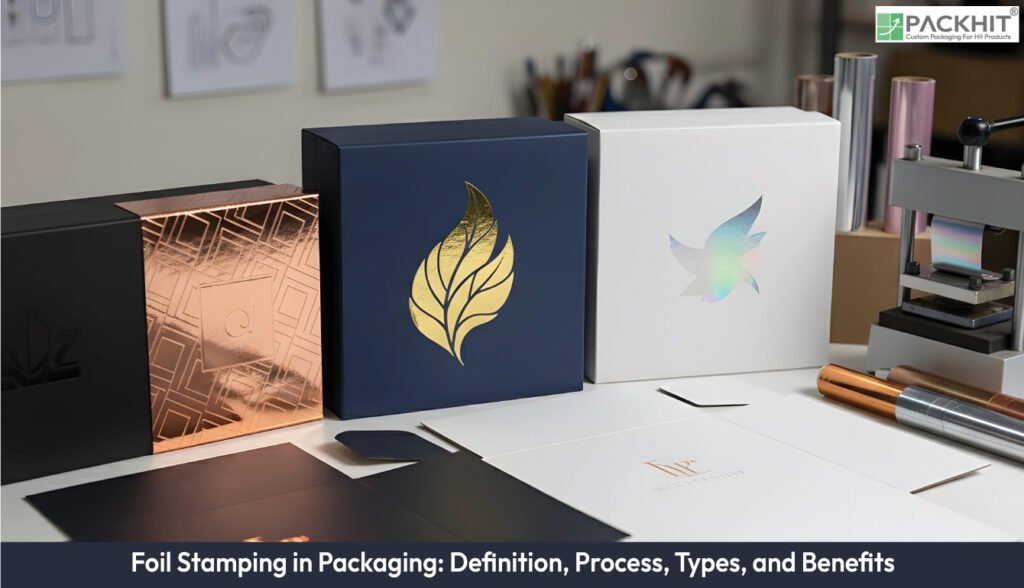

Foil stamping is a transfer process that moves a thin decorative film from a carrier to a finished surface using an activation mechanism such as heat or a reactive adhesive. The foiling element (the film) is typically a multilayer laminate consisting of a PET carrier, a release layer, the decorative layer (metallic vapour-deposited aluminium, pigmented ink, pearlescent or holographic microstructure) and an adhesive layer that either melts or bonds when the activation condition is met. The stamping tools (a metal die, polymer plate or laser-engraved cliché) provide the shape and localise heat/pressure. Classification by function separates decorative foils (metallic, matte, pigment), security foils (holographic, tamper-evident) and functional foils (barrier or conductive layers used in specialised packaging). Variable aspects include run length suitability, substrate compatibility and whether the transfer uses heat activation (hot foil), pressure plus adhesive (cold foil) or digitally controlled reactive adhesives (digital foiling).

What is the Importance of Foil Stamping in Packaging?

Foil stamping increases pack visibility, improves shelf pickup rates, and strengthens brand differentiation through reflective contrast and micro‑structured detail. Controlled reflectance from vapour‑deposited aluminium layers increases object–background separation on crowded shelves. Micro and structural embossing combined with stamped foil introduces depth cues that guide consumer focus toward brand marks or regulatory identifiers. Foil layers also support authentication functions through diffraction patterns and hologram matrices used on security‑sensitive packs, if counterfeiting risk rises. Gold and silver foils remain common in commercial production, although coloured foils with defined spectral shifts extend branding range in cosmetics cartons, premium food packs and electronics sleeves.

How Does the Foil Stamping Process Work in Packaging?

The foil stamping process converts a film on a carrier into a permanent or semi-permanent decoration by bringing the film into intimate contact with the substrate while applying a controlled combination of heat, pressure and time or by laminating foil to an adhesive-coated surface, then stripping the carrier.

Step 1: Prepare the Stamping Die

Engrave the stamping die so the image aligns with the approved artwork. Confirm the die relief depth, edge sharpness, and surface flatness during setup. Heat the die to the target range that supports stable transfer across repeated impressions. Deep artwork areas require firm structural support, and engraved lines demand uniform heat flow. Foil stamping in sectors such as confectionery cartons or spirits labels gains consistency when the die reaches thermal equilibrium before contact with the substrate. Foil and carrier release layers react predictably once the die achieves even heat distribution across each engraved region.

Step 2: Position the Foil

Mount the foil roll on the unwind shaft and thread it through the tension control path. Align the foil so the decorative layer reaches all active image zones. Set tension so the film stays flat across the platen during cycling. Uniform feed paths reduce incomplete patches and stray pick up on surrounding unprinted areas. Production lines in cosmetics and chocolate packaging often run wide webs, and consistent tension across the span limits wrinkles that weaken the metallic layer. Holographic films demand smooth tracking because diffraction patterns distort when tension spikes or slack spots form.

Step 3: Press and Transfer the Foil

Bring the heated die into contact with the foil and substrate to initiate the adhesive bond. Apply a force that matches substrate compressibility so the transfer reaches the entire image field. Reduce dwell time when substrate fibres start to scorch. Increase dwell time if the carrier lifts before the adhesive bonds. Web presses that handle cold foil stages rely on pressure instead of heat, yet the goal stays identical because uniform contact creates a clean release of the decorative layer. Metallic films used on premium liquor labels transfer more consistently when operators maintain line speed stability across the impression window.

Step 4: Inspect and Finish

Check the applied foil for even coverage, clean edges, and stable registration against printed graphics. Look for lift points at corners because foil tends to break near sharp transitions. Apply embossing passes or protective varnish after confirming transfer quality. Hot foil jobs in greeting cards and art prints often combine micro embossing with reflective layers, and inspection at this stage reveals defects before die cutting. Move the sheets or web to conversion only after confirming that hinge zones, folds, and structural panels hold the foil without cracks or loss of adhesion.

What are the Types of Foil Stamping Used in Packaging?

Packaging foils are applied using different methods depending on substrate, production run, and finish requirements. The main methods include hot stamping, cold inline foiling, and digital or transfer foiling. Hybrid techniques combine embossing or holographic effects for premium or security finishes.

1. Hot Foil Stamping

Hot stamping uses heated metal or polymer dies to activate the adhesive on the foil and bond it to the substrate. The process suits medium to long production runs and allows deep impressions when paired with embossing. It works well on paper, board, and coated surfaces.

2. Cold Foil Stamping

Cold foiling applies UV- or solvent-based adhesive onto the substrate and laminates thin foil to the adhesive before immediately stripping the carrier. This method supports high-detail graphics, long runs on labels and flexible packaging, and substrates that cannot tolerate heat.

3. Digital and Transfer Foiling

Digital foiling bonds foil to toner or specially prepared reactive coatings without metal dies. The method enables short runs, variable designs, and rapid turnaround. Digital foiling is ideal for prototypes, personalised packaging, and limited editions.

What are the Components and Finishes of Foil Used in Packaging?

Foils consist of a PET carrier, functional coatings, a decorative layer, and a heat- or UV-activated adhesive. Common finishes include metallic, coloured metallics, pigmented, pearlescent, holographic, and matte textures. Foil thickness is typically below 30 microns to conform to fine detail and embossing.

What are the Tooling Types Used in Foil Stamping?

Dies for foil stamping come in brass, magnesium, or laser-etched polymer. Brass dies provide durability and support fine detail, making them suitable for long runs. Magnesium dies offer a cost-effective option for short-run projects. Laser-etched polymer dies work well for digital-friendly setups. Selection depends on expected impressions, required detail resolution, and available budget for die fabrication.

What are the Benefits of Foil Stamping in Packaging?

Foil stamping provides multiple advantages in packaging, enhancing appearance, functionality, security, and production efficiency.

Enhanced Visual Appeal

Foil stamping increases visual salience through metallic, holographic, or pearlescent effects. Light reflectivity and specular highlights make packaging stand out and reinforce brand positioning.

Elevated Tactile Experience

Combining foil with embossing creates raised elements, adding tactile differentiation. Consumers can feel a premium quality, enhancing the perception of luxury or product grade.

Strengthened Security

Custom holographic or micro-structured foils prevent counterfeiting. Unique patterns or structures provide tamper-indicating features that protect high-value or sensitive products.

Improved Production Compatibility

Foil integrates with multiple printing processes, including lithography, flexography, offset varnish, and digital workflows. Manufacturers can apply foil as a finishing stage in hybrid production without disrupting earlier print processes.

Targeted Material Efficiency

Foil allows selective application on logos, text, or specific areas. Material use is reduced compared with full-surface metallization while retaining metallic impact on desired sections.

Optimised Cost Performance

Hot stamping offers cost efficiency for medium to long runs by amortising die costs. Digital foiling is cost-effective for short runs, variable data, or rapid proofing without requiring dies.

How do Production Factors Influence Foil Stamping Costs?

Foil stamping costs are influenced by die creation, skilled labour, setup time, and production variables. Multi-colour jobs require extra dies, while larger runs lower unit costs by spreading tooling expenses. Short runs increase prepress time as operators adjust heat, pressure, and foil alignment. Thick boards, duplex panels, or deep embossing extend dwell time and raise foil consumption. Laminated or coated substrates demand more adhesive and a slow machine speed, increasing the cost per unit. Speciality foils for gift boxes or promotional items may cause higher spoilage when tension or release coatings fluctuate. Costs stabilise once dies are locked, machine speed is consistent, and carrier draw remains uniform across the batch.

What are the Environmental and Recycling Considerations for Foil Stamping?

Metalised foils and PET carrier films can interfere with traditional paper recycling when foils are not separable. Foil construction, adhesive chemistry, and overall design directly affect recyclability and end-of-life processing.

- Adhesive Selection: Use water-dispersible or easily separable adhesives compatible with barrier requirements.

- Foil Choice: Opt for pigment or pearlescent foils that deposit minimal metallic content.

- Recyclable or Compostable Foils: Select foils certified for recyclability or industrial composting where available.

- Design Optimisation: Avoid covering entire panels with foil when recycling is a priority.

- Food-Safe Materials: Ensure adhesives and foils meet migration and food-safety standards, specifying intended end use for supplier certification.

What are the Key Applications of Foil Stamping Across Industries?

Foil stamping is widely used in various industries for packaging, including cosmetics, spirits, confectionery, premium consumer electronics packaging, pharmaceutical blisters and labels, and security documents where metallic finishes signal value or provide authentication.

- Cosmetics packaging uses selective silver or gold foils on cartons and boxes to highlight logos, brand accents, and premium appeal.

- Spirits and beverage labels combine foil with embossing to indicate a premium range and enhance shelf presence.

- Confectionery and flexible packaging apply cold foil highlights on laminate pouches to attract attention and improve visual impact.

- Pharmaceutical packaging uses tamper-evident holographic foils on blisters and labels for authenticity and security.

- Consumer electronics packaging incorporates foil for branding, decorative accents, and a premium finish perception.

Selection Considerations include foil type, stamping method, regulatory compliance, expected handling, and compatibility with downstream operations such as varnishing, lamination, or die-cutting.

What are the Challenges of Foil Stamping in Packaging?

Foil stamping involves several operational and material challenges that can affect transfer quality, substrate integrity, and overall production consistency.

- Substrate instability can prevent clean foil transfer and reduce durability.

- Surface resistance from textured or heavily coated substrates can block uniform foil adhesion.

- Material fragility in very thin substrates can lead to wrinkling or perforation under pressure.

- Recycling complexity occurs when certain metallised foils cannot be separated efficiently.

- Transfer inconsistency can result in incomplete or uneven foil application.

- Foil flaking can occur when adhesive or substrate interaction is inadequate.

How to Select the Right Foil Stamping Method?

Selecting the right foil stamping method depends on production requirements, substrate type, artwork complexity, and desired finish. The table below summarises when to choose hot, cold, or digital foiling based on key factors.

| Foil Method | Best Use | Key Strengths | Decision Factors |

|---|---|---|---|

| Hot Foil Stamping | Medium-to-long runs | Deep impressions, high-detail, durable transfer, premium finish | Die cost amortisation, substrate type, embossing/raised effects, unit cost targets |

| Cold Foil Stamping | High-speed inline web applications | Photographic coverage, efficient for flexible substrates | Maximum metallic coverage, substrate compatibility, environmental constraints, and run length |

| Digital Foil Stamping | Short runs, variable data, rapid changeovers | No dies required, supports personalisation, fast setup | Variable or personalised content, short runs, rapid proofs, unit cost flexibility |

Choosing the appropriate foiling method ensures optimal quality, efficiency, and cost-effectiveness. Consider run length, metallic coverage, personalisation needs, and substrate compatibility to make an informed decision.