Dielines provide structured templates that define cutting, folding, and assembly lines for packaging components, ensuring precise production and consistent brand presentation. Dielines are created to optimise panel arrangement, safe zones, and material usage, reducing waste and lowering costs. Collaboration with manufacturing ensures dielines accommodate substrate thickness, scoring, and finishing processes while supporting complex shapes, inserts, and protective structures. Applications extend across different packaging types, enhancing product protection, operational efficiency, and visual impact. Proper dieline planning accelerates printing, cutting, and assembly, maintaining high-quality output across industries such as food, cosmetics, pharmaceuticals, electronics, retail, and e-commerce.

- What is a Dieline?

- Why Does a Dieline Matter in Packaging?

- What Elements Must Appear on a Dieline in Packaging?

- How to Create a Dieline for Print and Packaging?

- 1. Measure Product Dimensions

- 2. Draft the Flat Pattern

- 3. Define Cut Lines and Score Lines

- 4. Set Bleed Areas and Safe Zones

- 5. Account for Material Thickness

- 6. Annotate Manufacturing Notes

- 7. Validate Digital and Physical Proofs

- 8. Finalise and Hand Off Production Files

- What Tools are Commonly Used for Creating Packaging Dielines?

- What is a Dieline Template in Packaging and How is it Used?

- Structural Definition and Layout

- Material and Thickness Specification

- Artwork Placement and Print Control

- Assembly and Glueing Guidance

- Production Consistency and Quality Assurance

- What are the Different Types of Packaging Dieline Templates?

- What are the Benefits of Dielines in Packaging?

- How do Dielines Affect Sustainability, Cost and Efficiency?

- How are Dielines for Packaging Used Across Different Industries?

- What are Common Dieline Mistakes in Packaging?

What is a Dieline?

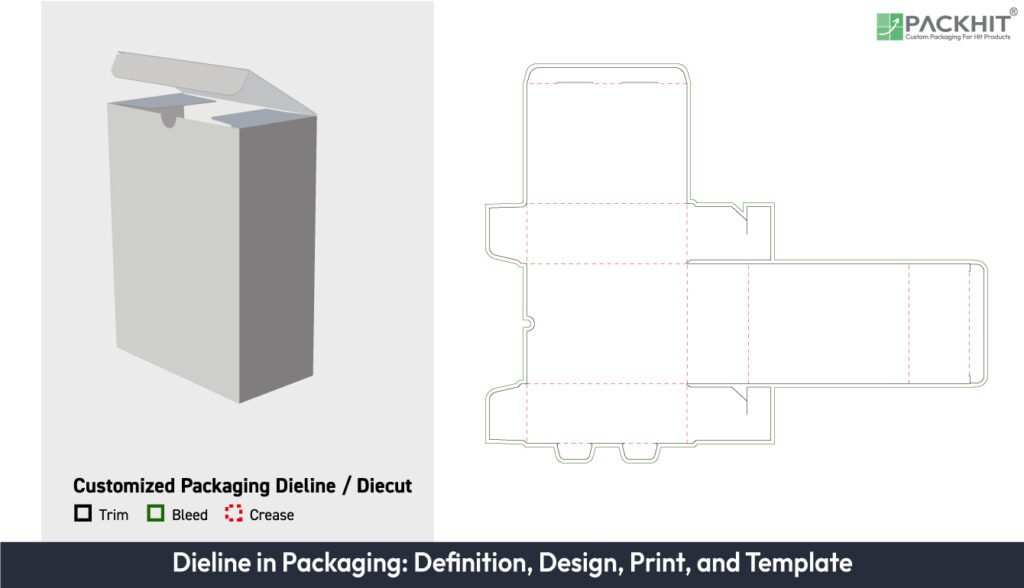

A dieline is a detailed flat layout that marks the geometry required to produce packaging. As a template and a process, a dieline is a digital file that maps cut lines, fold lines (score lines) and bleed areas to the physical printing substrate. The principal function of dieline is to guide production steps, including printing, die-cutting and folding, so that structural geometry and brand artwork align. In practical terms, the dieline acts as the geometric specification used across packaging design, print production and packaging engineering, and increases integration of parametric design systems and CAD/PLM workflows.

Why Does a Dieline Matter in Packaging?

A dieline matters in packaging for converting design intent into manufacturable geometry and reducing downstream errors. Correctly defined cut and fold geometry prevents mis-trims and lost artwork, and consistent application of bleed and safe-zone rules preserves product information and branding at trim. Measured impacts include material-waste reductions, development-cost reductions, AI (Artificial Intelligence) /VR (Virtual Reality)-assisted dieline tooling associated with faster design cycles.

What Elements Must Appear on a Dieline in Packaging?

Cut lines, fold/score lines, bleed areas, and safe zones must be defined on every production-ready dieline. Each element has a discrete role.

- Cut lines: guide trimming and define final panel edges; location must be explicit to align the die-cut tool with the artwork.

- Fold/score lines: indicate bending points where material will be scored or folded; placement governs structural integrity.

- Bleed areas: required as safety margins so printed imagery extends beyond the cut line; absence of bleed increases the risk of white trim edges.

- Safe zones: defined regions where critical content (text, logos, barcodes) sits away from trim and fold; they prevent loss of information during finishing.

- Visual-element placement: the layout for artwork and brand assets, placed relative to cut and fold lines to maintain legibility and appearance.

- Manufacturing notes: annotations for adhesives, grain direction, material thickness and any special die-cutting or finishing instructions; these ensure the factory reproduces the designer’s intent.

How to Create a Dieline for Print and Packaging?

Create a dieline by drafting a flat structural layout, adding production annotations, and checking dimensional accuracy against material tolerances before releasing files to manufacturing.

The steps to create a dieline are as follows:

1. Measure Product Dimensions

Measure product dimensions to set internal volume, flap reach, closure fit and panel allowances. Measurements record width, height, depth and any interference points created by tabs or openings, if structural parts shift under compression. Accurate measurements create the base geometry used in the flat pattern.

2. Draft the Flat Pattern

Draft the flat pattern as a single planar artwork file that holds structural geometry. CAD and vector tools such as Adobe Illustrator or ArtiosCAD create layers for perimeter cuts, slots, tabs and artwork alignment. Designers sketch concepts first, then convert them into precise vector paths.

3. Define Cut Lines and Score Lines

Define cut lines and score lines as separate vector strokes on a locked structural layer. Cut strokes specify perimeter edges and slot paths; score strokes define fold direction, hinge points and perforation paths. The dieline guides die-makers who form the hardened‑steel tool used during cutting.

4. Set Bleed Areas and Safe Zones

Set bleed areas and safe zones to protect artwork during trimming and folding. Bleed extends printed colour beyond trim; safe zones move text, logos and barcodes away from cuts or fold stress points. Printers tighten tolerances when substrates shrink or expand.

5. Account for Material Thickness

Account for material thickness by adjusting fold allowances, hinge offsets and tab engagement. Corrugated flutes, rigid board or thin paperboard each change the effective panel width. Geometry expands or compresses when the calliper varies across print runs.

6. Annotate Manufacturing Notes

Annotate manufacturing notes that specify grain direction, adhesive points, registration marks and assembly sequence. Notes guide press operators and die cutters during setup. Graphic designers, die cutters, and printers rely on these annotations to avoid misalignment or misfolds.

7. Validate Digital and Physical Proofs

Validate digital and physical proofs to confirm cut geometry, artwork registration and closure fit. Digital checks confirm vector accuracy; physical prototypes reveal scoring depth, resistance at hinges and tab interaction, if the substrate carries inconsistent stiffness.

8. Finalise and Hand Off Production Files

Finalise and hand off production files by locking structural layers, embedding registration marks and packaging the dieline, artwork and manufacturing notes. The final geometry drives the creation of the metal die and controls cutting, folding and assembly during manufacturing.

What Tools are Commonly Used for Creating Packaging Dielines?

Packaging dielines require precise design and structural planning. Various tools support designers in producing accurate and production-ready templates.

- Adobe Illustrator: Widely used for creating vector-based dielines, Illustrator allows precise panel layout, fold and cut lines, and artwork placement.

- ArtiosCAD: Specialised software for structural packaging design, ArtiosCAD enables 3D visualisation, material simulation, and prototyping of complex packaging formats.

- Dieline Generators: Online platforms provide customizable templates for standard box styles, sleeves, and inserts, accelerating the initial layout process and ensuring alignment with common industry standards.

What is a Dieline Template in Packaging and How is it Used?

A dieline template in packaging defines the precise cut, fold, and assembly structure required to produce boxes, cartons, and other packaging formats accurately. Packaging teams use dieline templates to connect structural design, material behaviour, artwork placement, and manufacturing requirements into a single production-ready layout.

The following headings explain the key functions, design considerations, and practical applications of dieline templates in packaging production.

Structural Definition and Layout

A dieline template sets cut paths, score lines, fold angles, bleed areas, and glue zones. Clear structural definition ensures accurate folding, clean edges, and correct final dimensions during conversion.

Material and Thickness Specification

Dieline templates document board type, calliper, grain direction, or flute orientation. Material specification prevents cracking at folds, compression loss, and deformation during packing and transport.

Artwork Placement and Print Control

Dieline templates establish safe zones, trim margins, and visible panels. Controlled placement protects logos, text, barcodes, and regulatory information from distortion near folds and seams.

Assembly and Glueing Guidance

Dieline templates include flap orientation, glue areas, and assembly sequence notes. Clear guidance reduces setup errors and improves consistency on automated and manual packing lines.

Production Consistency and Quality Assurance

Dieline templates standardise packaging output across print runs, suppliers, and regions. Consistent structures support repeatability, reliable filling-line performance, and predictable logistics handling.

What are the Different Types of Packaging Dieline Templates?

Dieline templates vary depending on the box construction and intended use. Folding carton templates support tuck-end cartons with thin paperboard and precise scoring. Sleeve templates define wrap-around panels with glue flaps and visibility zones. Corrugated box templates specify the geometry of the thicker board, including flute direction and slot tolerances. Rigid box templates separate base and lid layouts with wrap allowances and adhesive points. Tray and insert templates define internal geometry to secure products within the primary pack.

What are the Benefits of Dielines in Packaging?

Dielines provide a structured blueprint for designing and producing packaging, ensuring accuracy, efficiency, and cost-effectiveness.

- Accurate Cutting and Folding: Dielines guide precise placement of cut lines, folds, and panels, reducing errors during production.

- Consistent Brand Presentation: Proper dielines maintain artwork alignment, colour placement, and logo visibility across all units.

- Material and Cost Efficiency: Optimised dielines improve sheet or board usage, reducing material waste and lowering production costs.

- Faster Production and Workflow: Clear dielines streamline communication between design and manufacturing teams, accelerating setup and reducing errors.

- Enhanced Product Fit and Protection: Dielines ensure correct dimensions, fold allowances, and insert fits, improving product security and packaging functionality.

- Support for Complex Packaging Designs: Dielines allow the incorporation of sleeves, inserts, trays, and special folds, enabling innovative and functional packaging solutions.

How do Dielines Affect Sustainability, Cost and Efficiency?

Dielines play a critical role in material use, production costs, and operational efficiency in packaging design. Properly optimised dielines improve sustainability, reduce expenses, and streamline workflows.

- Material Waste Reduction: Efficient panel arrangement and shape nesting maximise board or sheet usage, reducing scrap by up to 15% and lowering environmental impact.

- Development Cost Savings: Optimised dielines shorten design and prototyping stages, cutting overhead and development costs by approximately 30%.

- Faster Design Iterations: AI-assisted and virtual-reality workflows accelerate dieline creation and modifications by around 25%, supporting quicker time-to-market.

- Production Efficiency: Accurate dielines reduce errors on press and finishing lines, minimise reprints and material loss, and maintain consistent quality across batches.

How are Dielines for Packaging Used Across Different Industries?

Dielines find applications in diverse industries by ensuring accurate, efficient, and brand-consistent packaging production.

- Food and Beverage: Folding cartons, pouches, and sleeve packaging rely on dielines to maintain product protection, portion control, and branding across retail units.

- Cosmetics and Personal Care: Rigid boxes, folding cartons, and sleeves use dielines to accommodate inserts, maintain visual appeal, and support premium finishes like embossing and foil stamping.

- Pharmaceuticals and Healthcare: Dielines guide secure folding cartons, blister pack sleeves, and labels to ensure product safety, regulatory compliance, and tamper-evident features.

- Electronics and Consumer Goods: Corrugated shipping boxes, trays, and inserts depend on dielines to provide cushioning, product separation, and structural stability during transport.

- Promotional and Retail Packaging: Point-of-purchase displays, sleeves, and gift boxes use dielines to achieve complex folds, precise assembly, and high visual impact for marketing campaigns.

- E-commerce and Logistics: Custom shipping boxes and mailer templates rely on dielines to optimise material use, reduce shipping damage, and ensure easy assembly and returns.

What are Common Dieline Mistakes in Packaging?

Dieline-related errors often lead to cutting, folding, or assembly problems during packaging production. Clear structural planning and accurate specifications reduce rework, waste, and delays. Common dieline issues and prevention methods are outlined below.

- Artwork Placed Too Close to Cut and Fold Lines: Dielines that allow artwork to extend into trim or fold zones risk text loss and graphic distortion. Clearly defining safe zones and positioning small text and fine details away from structural edges prevents trimming errors and preserves design integrity.

- Incorrect Bleed and Trim Settings: Dielines with insufficient bleed or misaligned trim marks create visible white edges after cutting. Prevention depends on applying printer-approved bleed values and verifying dieline accuracy before prepress approval.

- Material Thickness Not Reflected in the Dieline: Dielines that do not account for board calliper or flute size result in cracking, misaligned folds, or structural failure. Adjusting panel dimensions, fold allowances, and scoring depth to suit the chosen material ensures proper assembly and durability.

- Missing Structural and Assembly Notes: Dielines without glue zones, grain or flute direction, and assembly sequence notes lead to misassembly on the production floor. Prevention requires adding clear manufacturing annotations directly to the dieline file.