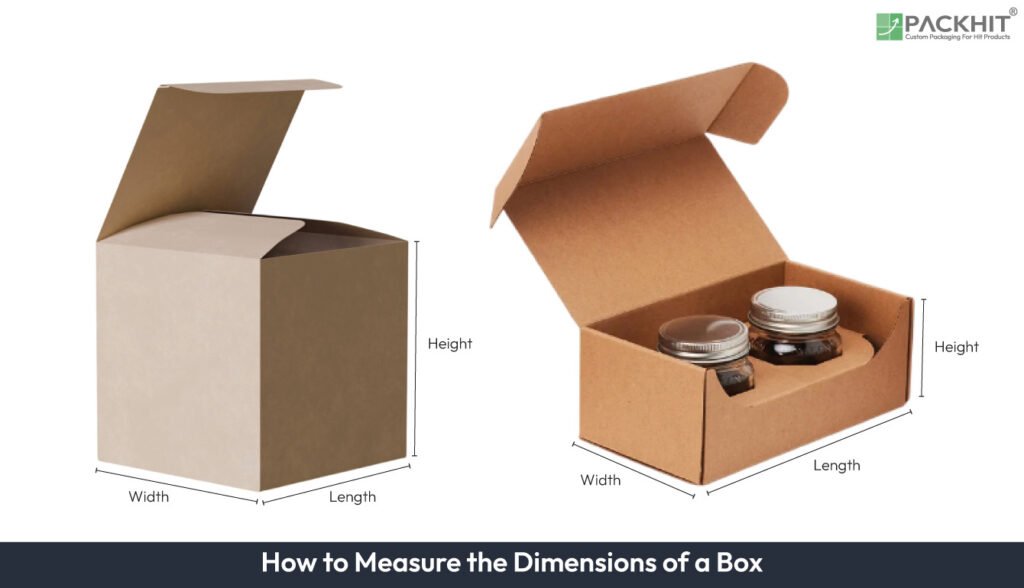

To measure the dimensions of a box, start by selecting the correct internal or external reference, preparing and squaring the box, then measuring length, width, and height before calculating volume and documenting results. Accuracy improves when measurements are repeated and averaged to offset panel bowing.

Box dimensions are typically measured using tools such as tape measures, steel rules, callipers, laser meters, and automated dimensioners, each offering different accuracy levels for packaging tasks. Tissue, pizza, cereal, and shoe boxes each require careful L × W × H readings taken across rigid faces, accounting for panel flex, hinges, wall thickness, or curvature. Accurate, box-specific methods prevent millimetre-level errors that affect packing and transport. For shipping, carriers require external L × W × H and volumetric weight based on their divisor, including girth when applicable. Manufacturers, however, need internal dimensions for product fit along with material and tolerance details. All records and labels should present consistent L × W × H notation with units, reference type, and tolerances to avoid rework. Common errors include using the wrong reference, incorrect orientation, ignoring board thickness, measuring across flaps, mixing units, poor averaging, and inconsistent rounding.

- What Tools are Used to Measure Box Dimensions?

- What are the Steps to Measure Box Dimensions?

- 1. Choose the Reference Point

- 2. Prepare the Box Sample

- 3. Measure the Length

- 4. Measure Width

- 5. Measure the Height

- 6. Calculate the Volume

- 7. Document Final Dimensions

- 8. Repeat Measurements and Average

- How to Measure Box Dimensions for Different Types of Boxes?

- How to Measure a Box for Shipping?

- What are the Common Measurement Errors While Measuring Box Dimensions?

What Tools are Used to Measure Box Dimensions?

The most common tools used to measure box dimensions are listed below:

- Tape measure: flexible steel or fibreglass tool used for external reads on assembled cartons; accuracy ±1–3 mm on short spans; practical for routine shipping checks.

- Steel rule or engineer’s rule: rigid edge used for flat panels, folded cartons, or dieline checks; accuracy ±0.5–1.0 mm; keeps edges square when reading cut scores.

- Vernier or digital callipers: sliding‑jaw tool used for thickness and small internal spans; accuracy0.01–0.02 mm; verifies corrugated flute thickness and insert clearances.

- Laser distance meter or digital dimensioner: optical device used for tall crates or pallet stacks; accuracy ±1–5 mm depending on range; records L, W, H faster than manual tools.

- Automated box dimensioner: an inline scanner used in fulfilment and carrier hubs; captures three axes and computes dimensional weight from volume; reduces manual entry errors.

What are the Steps to Measure Box Dimensions?

The steps to measure the box dimensions are given below:

1. Choose the Reference Point

Choose the reference point by deciding whether the job needs internal or external reads, because internal values guide product fit while external values influence freight and pallet layout. US manufacturers use internal reads for snug product placement and external reads for shipping bills, if carriers apply dimensional‑weight rules.

2. Prepare the Box Sample

Prepare the box sample by assembling it on a flat surface and removing inserts or padding so the panels sit square. This step gives consistent lines for measurement and reduces skew if the corrugated board shows curl from storage or humidity.

3. Measure the Length

Measure length (L) along the longest horizontal line. Keep the rule flat, keep eyes level with the reading, and avoid measuring across curved or crushed edges because corrugated fibreboard compresses near impact points.

4. Measure Width

Measure width (W) across the adjacent side perpendicular to the length, placing the tape or rule against the interior or exterior face without crossing flap edges. Read the shortest horizontal span because cartons from mass production often show minor panel bowing.

5. Measure the Height

Measure height (H) from the bottom panel to the top edge of the closed flaps, keeping the tape or rule against the interior or exterior face, depending on the reference. Read the point where the panel stops rising; crushed edges or bowed walls cause a 2–3 mm variation, so take a second reading for confirmation.

6. Calculate the Volume

Calculate the volume by multiplying the measured length, width, and height (L × W × H) in one unit. This single value helps estimate dimensional weight for carriers and confirms whether the internal cavity meets product‑fit targets. Keep units consistent across all measurements.

7. Document Final Dimensions

Record details as L × W × H with unit and reference. Add the tool type if the job relies on tight tolerances. Consistent notation prevents mix‑ups between metric and inch systems, a common source of rework in US manufacturing.

8. Repeat Measurements and Average

Repeat and average across two or three points along each axis. Corrugated panels bow slightly, especially on long spans, so averaging yields a truer value. This step reduces errors that appear when quoting custom cartons from supplier dielines.

How to Measure Box Dimensions for Different Types of Boxes?

Measure each box separately with the same tool and reference type so the record stays consistent. Internal reads support product fit, if the item sits tight in the cavity; external reads support freight checks on stacked units.

Tissue Box Dimensions

To measure tissue box dimensions, read the external length, width, and height across the rigid faces while the carton stays closed. These boxes use thin paperboard, so panel flex changes readings if the sides bow from moisture.

Pizza Box Dimensions

To measure pizza box dimensions, read length, width, and then height in that order. Hold the flat blank against its folded edges and record the external length first because square pizza cartons use matched panels. Read width across the adjacent span, keeping the rule against the rigid faces. Measure height last on an assembled sample, if the lid hinge lifts the front panel, because this hinge raises the closed height by 2–3 mm.

Cereal Box Dimensions

To measure cereal box dimensions, measure length, width, and height (L × W × H) after squaring the paperboard panels. Read the internal spans first, then take a second point on the length, if the side walls curve after filling and shift the internal cavity by 1–2 mm.

Shoe Box Dimensions

To measure shoe box dimensions, measure the external length, width, and height across the telescoping lid and bottom. These boxes use rigid paperboard, so thickness adds clearance; subtract wall build, if internal fit is required for tight footwear placement.

How to Measure a Box for Shipping?

Measure the closed, assembled box and record external L × W × H in the carrier’s preferred unit; then compute volumetric weight using the carrier’s divisor and compare with actual mass. Seal the box as it will be shipped before measuring. For girth‑sensitive carriers, calculate girth = 2 × (W + H) and report length + girth if required by the carrier.

Which Dimensions Should be Given to the Box Manufacturer?

Provide internal assembled dimensions for product fit, plus material spec and required tolerance; add the desired external dimensions if shipping or pallet constraints apply. Also supply product drawings, insert thicknesses, and required print/layout files so the supplier can derive the blank (dieline) and panel widths correctly.

What are the Common Measurement Errors While Measuring Box Dimensions?

Common measurement errors arise from seven recurring factors that are detailed below:

Wrong reference

Wrong reference creates size errors because internal and external reads support different tasks. Internal values describe product fit, for example, a 60 mm candle jar or a 120 mm cosmetic bottle. External values describe freight size, such as pallet layout or carrier dimensional‑weight brackets. Write the reference beside every L × W × H entry because US packaging teams often mix units across projects.

Incorrect orientation

Incorrect orientation occurs when the second‑longest panel is recorded as the length. Length identifies the longest axis in the box’s shipping position, for example, the 300 mm axis of a small tuck‑end carton commonly used in cosmetic packaging. Stating orientation avoids misprints on dielines and wrong pallet fit during production runs.

Ignoring board thickness

Ignoring board thickness produces tight internal clearance because corrugated and paperboard grades vary from 0.3 mm SBS to 5 mm double‑wall flutes. Subtract the total wall build when calculating internal fit, if inserts, wraps, or foil layers change the usable cavity.

Measuring across flaps or protrusions

Measuring across flaps or protrusions inflates external size because extended flaps, hanging tabs, or fitment arms sit outside the true panel edges. Close the box fully and read against the rigid faces; include flaps only if the flap occupies shipping volume on the conveyor scale.

Unit mismatch

Unit mismatch happens when mm and inch entries mix in the same record. State one system per line, for example, 300 × 200 × 150 mm or 11.8 × 7.9 × 5.9 in. Many US manufacturers keep mm for dielines and in for carrier forms, so cross‑check before quoting.

Poor Averaging

Poor averaging introduces bow‑related error because corrugated panels flex over long spans. Read two or three points along each axis and average them. Averaging matters on cosmetic mailers, subscription boxes, and any carton cut from lightweight E‑flute where wall curvature increases.

Wrong rounding

Wrong rounding causes mismatches between production and freight because manufacturing records millimetre precision, while carrier brackets use centimetres. Apply one rounding rule per workflow, for example, nearest millimetre for box plants and nearest centimetre for shipping forms.