To measure a pizza box dimension, record its length, width, height, and board thickness. Use a retractable steel tape or steel rule for length, width, and height, and a digital caliper for board thickness and small gaps. Common errors include using external dimensions, measuring across folded flaps or glued overlaps, ignoring board thickness or flute profile, and reporting center values without corner checks. For precision, record pizza thickness with non-compressible shims, verify headspace, and confirm assembled external L × W × H for shipping and storage. Pizza box sizes fall into six common categories, with examples such as small 21.6 × 21.6 × 3.2 cm (216 × 216 × 32 mm); standard 25.4 × 25.4 × 3.8 cm (254 × 254 × 38 mm); medium 31.8 × 31.8 × 4.4 cm (318 × 318 × 44 mm); large 36.8 × 36.8 × 5.1 cm (368 × 368 × 51 mm); extra-large 41.9 × 41.9 × 5.1 cm (419 × 419 × 51 mm); and jumbo 46.9 × 46.9 × 5.7 cm (469 × 469 × 57 mm). Accurate internal measurement preserves crust and toppings; oversized boxes create stacking and transport issues, while undersized boxes risk crushing the product.

- Steps to Measure Pizza Box Dimensions

- 1. Measure the Length (L)

- 2. Measure the Width (W)

- 3. Measure the Height (H)

- 4. Measure Board Thickness and External Dimensions

- Common Measurement Errors for Pizza Box Dimensions

- Tips for Accurate Measurement of Pizza Box Dimensions

- Pizza Boxes with Their Dimensions (Inches, cm, mm) and L × W × H

- Pizza Box Dimensions for Stacked Pizzas (Multi-Layered Pizza) and Deep-Dish Pizzas

- How Do Pizza Box Dimensions Influence Pizza Quality During Storage and Transport?

- How to Measure a Triangular Pizza-Slice Box?

Steps to Measure Pizza Box Dimensions

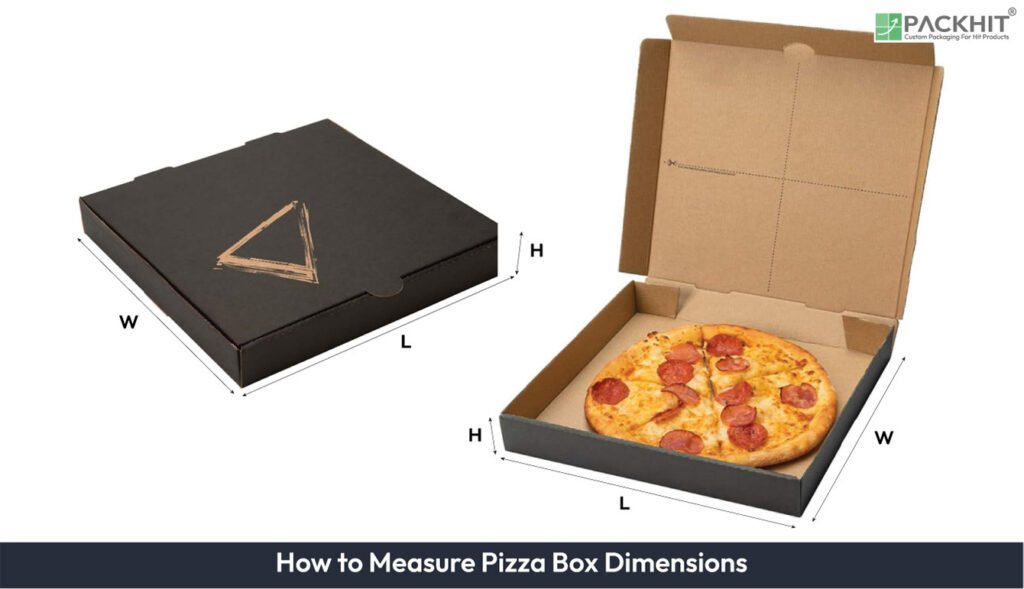

To measure pizza box dimensions, record the internal length, width, and height because these three units determine pizza fit and headspace. Take each value with a retractable steel tape or rigid rule, and use a digital caliper for thickness and narrow gaps. The steps for accurately measuring the pizza box dimensions are as follows:

- Measure the Length (L)

- Measure the Width (W)

- Measure the Height (H)

- Measure Board Thickness and External Dimensions

1. Measure the Length (L)

Measure the length inside the assembled box from one inner wall to the opposite inner wall at the base midline. Lay a steel tape flat on the base and read to the nearest 1/16 in (≈1 mm). If the box is square, measure both axes and report the larger as L. Check at the centre and near corners; record the smallest internal value.

2. Measure the Width (W)

Measure the width of the shortest internal span across the base at the midline. Use a steel tape or ruler and read to 1/16 in (≈1 mm). For square boxes, width equals length; for rectangular boxes, state L × W. Measure at centre and at each corner; record the minimum usable value.

3. Measure the Height (H)

Measure the height with the lid closed but not pressed. Place non-compressible shims to simulate pizza thickness, if needed (example: 1/8 in / 3 mm plastic spacer). Measure from the base interior to the lid interior at the centre and at a corner; record the smaller value. Take measurements at the centre and a corner; record the smaller value. Usable headspace = pizza height + 6–25 mm extra.

4. Measure Board Thickness and External Dimensions

Measure the board thickness at a fold or cut with a digital caliper; note the flute type (C‑flute, E‑flute). Record in mm. Measure the assembled box’s external L × W × H for shipping. External footprint = internal footprint + 2 × effective board thickness (including folds and glued overlaps).

Common Measurement Errors for Pizza Box Dimensions

Common measurement errors for pizza box dimensions are:

- Measuring external dimensions instead of the internal ones.

- Measuring across folded flaps or glued overlaps, producing an oversized internal reading.

- Reading measurements while the lid is depressed results in an underestimate of usable height.

- Ignoring board thickness and flute when converting flat blank panel widths to the assembled internal footprint.

- Failing to state whether values are internal or external creates procurement and manufacturing ambiguity.

- Neglecting corner versus centre checks and reporting only centre space, missing smaller usable spaces at corners.

- Reporting assembled external dimensions without specified measurement points or manufacturing tolerances prevents repeatable verification.

Tips for Accurate Measurement of Pizza Box Dimensions

To accurately measure the pizza box dimensions, follow the tips below:

- Measure internal length, width, and usable height at the centre and at each corner using a retractable steel tape.

- Measure board thickness with a digital caliper at a cut or fold and note flute grade; record thickness in mm.

- Check clearances and apply 0.25–0.5 in side clearance per side and 0.25–1.0 in headspace.

- Verify external assembled L × W × H and delivery-bag clearance; convert flat widths to internal values by subtracting overlaps, glue tabs, and tuck allowances.

- Request a physical sample and re-measure assembled internal dimensions; accept only if values meet specified tolerance, such as ±3 mm.

- Re-measure after any die change, board-grade change, or planned dimensional increase; compare measurements to procurement specifications and log results.

Pizza Boxes with Their Dimensions (Inches, cm, mm) and L × W × H

Pizza boxes come in a variety of sizes to accommodate different pizza diameters. They are usually measured in Length × Width × Height, and knowing the conversions between inches, centimeters, and millimeters can help manufacturers. The table below lists six fixed categories in inches, centimetres, and millimetres and helps match each format to pizza diameter and required headspace.

| Category of Pizza Box | Pizza Box Dimensions (Inches, Centimetres, Millimetres) | Recommended Pizza Box Dimensions (L × W × H) |

|---|---|---|

| Personal / Small Pizza Box | 8.5 × 8.5 in (21.6 × 21.6 cm) (216 × 216 mm) | 8.5 × 8.5 × 1.25 in |

| Standard Pizza Box | 10 × 10 in (25.4 × 25.4 cm) (254 × 254 mm) | 10 × 10 × 1.5 in |

| Medium Pizza Box | 12.5 × 12.5 in (31.8 × 31.8 cm) (318 × 318 mm) | 12.5 × 12.5 × 1.75 in |

| Large Pizza Box | 14.5 × 14.5 in (36.8 × 36.8 cm) (368 × 368 mm) | 14.5 × 14.5 × 2.0 in |

| Extra-large Pizza Box | 16.5 × 16.5 in (41.9 × 41.9 cm) (419 × 419 mm) | 16.5 × 16.5 × 2.0 in |

| Jumbo Pizza Box | 18.5 × 18.5 in (46.9 × 46.9 cm) (469 × 469 mm) | 18.5 × 18.5 × 2.25 in |

TThe dimension ranges in the table give a simple reference point for picking a box size that matches common pizza formats across small, medium, large, and jumbo groups.

Pizza Box Dimensions for Stacked Pizzas (Multi-Layered Pizza) and Deep-Dish Pizzas

Pizza boxes for stacked or deep-dish pizzas are sized taller and sturdier than standard boxes to accommodate multiple layers without squashing. The table below shows recommended pizza box dimensions for stacked pizzas and deep-dish pizzas, along with inches, centimetres, and millimetres units for easy specification and supplier reference.

| Category | Typical Pizza Size | Recommended Pizza Box Dimensions (L × W × H) | Dimensions in Inches/cm / mm |

|---|---|---|---|

| Stacked Pizzas (Two Standard Pizzas in One Box) | 12″ pizzas | 12.5″ × 12.5″ × 4″ | 12.5″ (31.8 cm / 318 mm) × 12.5″ (31.8 cm / 318 mm) × 4″ (10.16 cm / 102 mm) |

| 14″ pizzas | 14.25″ × 14.25″ × 4.5″ | 14.25″ (36.2 cm / 362 mm) × 14.25″ (36.2 cm / 362 mm) × 4.5″ (11.4 cm / 114 mm) | |

| 16″ pizzas | 16.5″ × 16.5″ × 5″ | 16.5″ (41.9 cm / 419 mm) × 16.5″ (41.9 cm / 419 mm) × 5″ (12.7 cm / 127 mm) | |

| Deep-Dish Pizzas | 10″ deep-dish | 11″ × 11″ × 3.5″ | 11″ (27.9 cm / 279 mm) × 11″ (27.9 cm / 279 mm) × 3.5″ (8.9 cm / 89 mm) |

| 12″ deep-dish | 13″ × 13″ × 4″ | 13″ (33 cm / 330 mm) × 13″ (33 cm / 330 mm) × 4″ (10.16 cm / 102 mm) | |

| 14″ deep-dish | 15″ × 15″ × 4.5″ | 15″ (38.1 cm / 381 mm) × 15″ (38.1 cm / 381 mm) × 4.5″ (11.4 cm / 114 mm) |

The dimension ranges in the table establish fixed internal footprints for stacked and deep-dish formats. Consistent height allowances prevent crust compression, and defined length‑to‑width ratios maintain slice clearance during storage and transport. Clear sizing groups support faster specification decisions for manufacturers.

How Do Pizza Box Dimensions Influence Pizza Quality During Storage and Transport?

Pizza box dimensions influence pizza quality during storage and transport, such as:

- Internal footprint controls pizza contact, as inadequate side clearance causes edge contact.

- Greater headspace reduces lid contact and topping smears; too little headspace causes crushed crust.

- Larger internal volume increases enclosed air mass, altering cooling rate and condensation risk.

- Use insulation or closer-fitting boxes if temperature retention is critical.

- Larger boxes raise sliding and stacking issues and may not fit delivery bags or racks.

- Add anti-slip inserts, adjust bag size, or limit flat-pack stack height if transport stability is required.

Why are Internal Measurements Necessary for a Pizza Box?

Internal measurements are crucial to ensure the pizza fits perfectly inside the box without being squished. They prevent the crust or toppings from touching the lid, which helps maintain the pizza’s shape and presentation. Proper internal dimensions also allow for the right amount of headspace, which controls steam buildup and keeps the crust from getting soggy. In short, accurate internal measurements are key for preserving quality, appearance, and temperature during storage and delivery.

How to Measure a Triangular Pizza-Slice Box?

To measure a triangular pizza slice box, record three measurements: length, width, and height. First, measure the base length, which is the longest straight edge that holds the crust. Next, measure the width across the widest part of the box, taken at a right angle to the base. Then measure the apex-to-base height, which is the distance from the tip of the triangle to the centre of the base. For single-slice wedge boxes, the base length is usually between 6 and 9 inches, with smaller slices around 6 inches and larger slices closer to 9 inches. If the slice has thick or heavy toppings, also measure the internal height at the centre of the wedge to ensure there is enough headspace.