To measure shoe box dimensions, prepare the box by clearing its contents, gather precise tools, and record internal length, width, and height using orthogonal spans that match how the shoes sit inside. Then check wall thickness, compute external dimensions by adding twice the board thickness to each axis, and convert and round units only after all metric calculations. Standard shoe box sizes vary by category from men’s trainers to women’s shoes, kids’ footwear, and tall boots, with internal ranges reflecting expected product fit and regional packing practices. For different packing orientations, measure spans in the position the shoes occupy, whether side-by-side, stacked, or upright for boots, ensuring the readings reflect actual storage form. Common mistakes while measuring show box dimensions include using the wrong envelope, measuring with the lid on, taking diagonal readings, ignoring wall thickness, mixing units, leaving insufficient clearance, and misplacing the tape.

To communicate dimensions clearly, label each axis as internal or external, give units consistently, and include corrugation thickness so manufacturers and carriers can interpret tooling and freight requirements accurately. Because shipping charges depend on external dimensions, carriers convert the measured cubic volume into volumetric weight, making precise external readings essential for accurate billing.

- What are the Steps to Measure Shoe Box Dimensions?

- 1. Prepare the Box

- 2. Gather the Tools

- 3. Measure Internal Length

- 4. Measure Internal Width

- 5. Measure Internal Height

- 6. Check Wall Thickness

- 7. Compute External Dimensions

- 8. Convert and Round

- What are the Standard sizes of Shoe Boxes?

- How to Measure a Shoe Box for Different Packing Orientations and Shoe Types?

- What are the Common Mistakes to Avoid While Measuring Shoe Box Dimensions?

- Wrong Envelope

- Lid-on Readings

- Diagonal Measurements

- Ignoring Wall Thickness

- Unit Mix

- Insufficient Clearance

- Poor Placement of Tape

- How to Communicate Shoe Box Dimensions to Manufacturers, Suppliers and Carriers?

- How Do Box Dimensions Alter Shipping Charges?

What are the Steps to Measure Shoe Box Dimensions?

The steps to measure shoe box dimensions are listed below:

- Prepare the Box

- Select Units

- Measure Internal Length

- Measure Internal Width

- Measure Internal Height

- Check Wall Thickness

- Compute External Dimensions

- Convert and Round

1. Prepare the Box

Prepare the box by clearing all contents, because loose tissue or inserts distort internal readings and create inconsistent contact points for the tape. Set the box on a flat surface. If the lid blocks the opening, lift or remove it. The container sits square only when all panels rest level.

2. Gather the Tools

Gather the tools by placing a tape measure with millimetre and inch marks, a steel rule or calliper, and a stable flat surface within reach. These tools record internal spans with fewer alignment errors, if the carton uses tight tolerances common in UK packaging runs.

3. Measure Internal Length

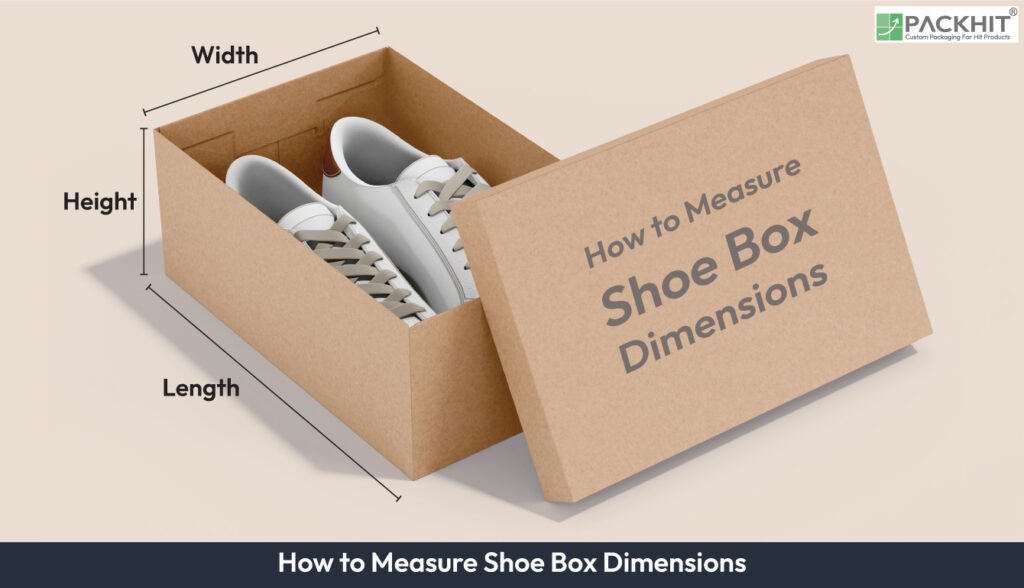

Measure internal length against the longest span inside the base. Place the tape flat against one internal wall and extend it to the opposite wall at the point where the shoe’s longest axis sits. Length values, such as 340 mm, anchor the carton’s size class in standard footwear packaging.

4. Measure Internal Width

Measure the internal width across the opening at right angles to the measured length. Keep the tape flush along the base edges. Width determines side‑by‑side packing for trainers and flat shoes if the product requires lateral clearance for inserts.

5. Measure Internal Height

Measure internal height from the internal base to the point where the lid meets the side panel without compression. Height varies widely for boots and stacked sandals. Height readings reflect the packing method, if the protective paper adds extra volume.

6. Check Wall Thickness

Check wall thickness with a steel rule or calliper. Single‑corrugated board used in common shoe cartons measures about 3.175 mm, and this value defines the external size. Thickness varies by material grade, if the carton uses heavy stock for shipping durability.

7. Compute External Dimensions

Compute external dimensions by adding twice the measured wall thickness to each internal axis. External readings form the basis of freight calculations and pallet loads in UK distribution centres. State the corrugation grade if suppliers compare tooling tolerances.

8. Convert and Round

Convert and round dimensions according to the buyer’s requested unit. Internal metric values convert to cubic metres for CBM records by dividing the volume in cubic centimetres by 1,000,000. Round inch conversions only after all metric calculations, if the supplier uses imperial-only order forms.

What are the Standard sizes of Shoe Boxes?

The standard sizes of shoe boxes cover internal dimension ranges used across trainers, boots, heels and kids’ shoes.

The table below shows standard sizes by shoe category, such as trainers, boots and heels, because regional sizing rules alter internal length and width ranges, and packing method changes the final envelope, if brands place pairs flat, stacked or with moulded inserts.

| Category (examples) | Internal length (cm / in) | Internal width (cm / in) | Internal height (cm / in) |

|---|---|---|---|

| Men’s trainers (e.g. running shoes, sneakers) | 33–36 cm / 13.0–14.2 in | 21–24 cm / 8.3–9.4 in | 10–13 cm / 3.9–5.1 in |

| Women’s shoes (e.g. flats, low boots) | 28–32 cm / 11.0–12.6 in | 18–21 cm / 7.1–8.3 in | 8–11 cm / 3.1–4.3 in |

| Kids’ shoes (examples: toddlers, children) | 17–27 cm / 6.7–10.6 in | 11–15 cm / 4.3–5.9 in | 5–8 cm / 2.0–3.1 in |

| Boots and tall footwear (example: knee or calf boots) | variable; length follows shoe size | variable; width follows sole width | 15–40 cm / 5.9–15.7 in (model dependent) |

The ranges mentioned above define the internal volume required for predictable product fit across adult and juvenile footwear. Clearance allowances guide UK manufacturers that record tight tolerances in millimetres for die-cut layouts and freight planners that convert internal figures into external envelopes for CBM calculations.

How to Measure a Shoe Box for Different Packing Orientations and Shoe Types?

Choose the packing orientation that matches how shoes sit inside the box and measure the internal spans in that position. Use side‑by‑side, alternating, or stacked formats. Measure the boots upright, and if that matches how the shaft sits in the container. Measure sandals and flat shoes with insoles in place to record the footprint as stored. This keeps length, width and height consistent with production checks.

- Side‑by‑side packing: record the internal length to fit the longer shoe axis plus clearance.

- Stacked packing: record height to cover stacking and any protective paper.

- Ankle and tall boots: record height with the shaft upright if the packed form stays upright.

What are the Common Mistakes to Avoid While Measuring Shoe Box Dimensions?

The most common mistakes to avoid while measuring a shoe box’s dimensions are listed below:

Wrong Envelope

A wrong envelope produces incorrect box selection because internal readings define fit, and external readings define freight calculations. Internal spans record usable volume for shoes, inserts, or tissue, if the product requires extra clearance.

Lid-on Readings

Lid-on readings create reduced height values because closed lids compress the upper edge of the carton. Internal height must record the base-to-lid‑seat distance if the lid sits over the sidewalls rather than flush.

Diagonal Measurements

Diagonal measurements distort length and width because diagonals add unwanted margin. Orthogonal spans match footwear axes and match common UK production tolerances, if the shoe shape requires tight width control.

Ignoring Wall Thickness

Ignoring wall thickness reduces external estimates because corrugated board adds measurable bulk. Single‑corrugated stock adds about 3.175 mm per wall in common UK cartons, if the board grade stays consistent across the run.

Unit Mix

Unit mix creates incompatible entries because centimetres and inches record different granularity. Dimension sets must keep one unit system per entry if carriers or manufacturers specify strict recording rules.

Insufficient Clearance

Insufficient clearance truncates internal size requirements because wrapping paper or moulded inserts expand the footprint. Clearance counts most for trainers or boots if the packing orientation stacks components vertically.

Poor Placement of Tape

Poor placement of tape introduces slack or misalignment because lifted tape edges fail to follow the inner walls. Flat contact records consistent spans for length, width and height, if the carton has curved or deflected panels.

How to Communicate Shoe Box Dimensions to Manufacturers, Suppliers and Carriers?

To communicate shoe box dimensions to manufacturers, suppliers and carriers, state each measurement as a number, a unit, and an internal or external label.

Record internal dimensions for product fit and external dimensions for freight calculations, if the carton wall grade changes the outer envelope. Add corrugation thickness values in millimetres, such as 3.175 mm single‑wall stock. Provide metric and imperial conversions only after confirming which unit the receiving party logs into its system.

Recommended notation examples include the following:

- Internal: 34.0 cm × 22.0 cm × 12.0 cm (L×W×H, internal)

- External: 34.6 cm × 22.6 cm × 12.6 cm (L×W×H, external, single‑corrugated 3.175 mm walls)

- Imperial: 13 in × 8.7 in × 4.7 in (L×W×H, internal, rounded to 0.1 in or whole inch)

List all three axes on one line to avoid dimension reversals if multiple suppliers compare tooling. Note the measurement orientation used during checks, because shoe placement affects the recorded internal spans.

How Do Box Dimensions Alter Shipping Charges?

Box dimensions alter shipping charges because carriers calculate volumetric weight from the external envelope that surrounds the product. External length, width, and height define the cubic volume used for pallet planning and carton consolidation in UK fulfilment centres.

Compute CBM from external centimetre values by multiplying the three axes and dividing by 1,000,000. State the result to three significant figures. Carriers apply their volumetric conversion factor to this external volume if they use dimensional weight for billing.