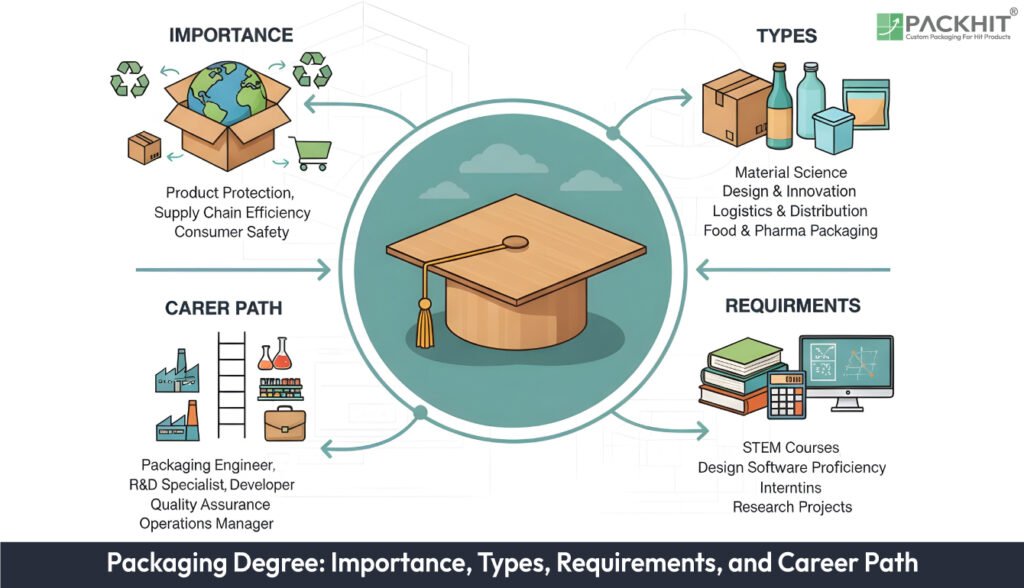

Packaging Degree refers to the academic programmes that teach material science, structural design, testing, graphics, and regulatory principles used to create functional packaging. Packaging degree explains how formal training aligns technical skills with industry, compliance, and performance requirements in UK manufacturing. The packaging degree types outline undergraduate, postgraduate, vocational, dual, certificate, and apprenticeship routes available for different career goals. Packaging degree requirements define entry criteria, subject prerequisites, portfolios, technical readiness, placements, and apprenticeship conditions. Packaging degree career paths describe roles in engineering, design, quality, regulation, supply chain, research, and cross-disciplinary fields. Packaging degree skill development shows how labs, CAD work, testing, documentation, placements, and apprenticeships build measurable competence. Packaging degree selection guidance explains how to choose programmes based on level, curriculum depth, prerequisites, tools, placements, and progression routes.

- What is a Packaging Degree?

- Why is a Packaging Degree Important?

- What are the Different Types of Packaging Degrees?

- Bachelor’s Degree In Packaging Science Or Packaging Engineering

- Associate Degree Or Higher National Diploma In Packaging Technology

- Master’s Degree In Packaging Engineering Or Industrial Design

- Dual BS / MS Packaging Science Degree

- Postgraduate Certificates And Short Courses In Packaging Technology

- Degree Apprenticeship In Packaging Or Related Engineering Fields

- What are the Requirements for A Packaging Degree?

- 1.Academic Entry Criteria

- 2. Subject‑Specific Prerequisites

- 3. Portfolio Or Practical Evidence

- 4. Technical Skill Readiness

- 5. Placement Or Co‑Op Eligibility

- 6. Apprenticeship Assessment Conditions

- What are the Career Paths After a Packaging Degree?

- Packaging Engineering Roles

- Packaging Design Positions

- Quality and Regulatory Roles

- Supply Chain and Logistics Roles

- Research and Postgraduate Pathways

- Specialist or Cross‑disciplinary Career Routes

- How do Packaging Programmes Develop the Required Technical Skills?

- How to Select the Right Packaging Degree Programme?

What is a Packaging Degree?

A packaging degree is an academic programme that teaches the technical, scientific and design principles used to create functional packages for products, such as food, cosmetics or pharmaceuticals. The curriculum defines how materials behave, how structural designs support load during transit and how graphics communicate information on pack panels. Universities classify these programmes across different levels, such as bachelor’s degrees, master’s degrees or research degrees, and some institutions embed structured work placements, such as two co-op blocks or a year-in-industry assignment. The subject spans materials science, barrier testing, print processes and regulatory topics, such as food-contact compliance and packaging waste rules. Routes into the field vary: students may enter through packaging science, industrial design or graphic design degrees; progression paths include advanced programmes such as packaging engineering master’s degrees or integrated BS / MS pathways that connect undergraduate and postgraduate study. The degree trains graduates to quantify package performance through measurable criteria, such as compression force, seal strength or oxygen transmission rate, and to convert those metrics into specifications used by manufacturers and suppliers.

Why is a Packaging Degree Important?

A packaging degree carries importance because it aligns technical skills with the material, structural and regulatory demands that control how products move from production to consumers. Programmes tie laboratory testing, materials science and design tasks to measurable outputs, such as seal‑strength values, compression‑force data or OTR figures. UK manufacturers compare graduates by these metrics if applicants apply for engineering or QA roles. The degree also links academic modules with workplace tasks found in co‑op blocks or apprenticeships, where learners complete line‑trial observations, specification drafting or print‑process checks. Programmes match employer expectations because manufacturers in the UK assess CAD accuracy, prototype‑sample precision and documentation quality through portfolios and on‑site evaluations.

A packaging degree adds relevance for design‑focused or engineering‑focused applicants who enter through graphic design, industrial design, packaging science or vocational packaging‑technology routes. Undergraduate, associate and certificate pathways build the skill base described in context, and advanced master’s degrees or dual BS/MS sequences develop research capability in barrier behaviour, structural modelling or material substitution. Degree‑apprenticeship structures aggregate academic study with EPA conditions; evidence covers workplace tasks such as pallet‑pattern checks or sample preparation. These combined routes shape predictable career progression across engineering, design, regulatory or cross‑disciplinary roles, such as patent‑attorney training, if a graduate adds legal study after completing a technical degree.

What are the Different Types of Packaging Degrees?

Different types of packaging degrees include structured academic routes that train students in materials, structural design, regulatory controls and production methods used in UK manufacturing. These degree types sit across undergraduate, postgraduate and apprenticeship pathways.

- Bachelor’s Degree in Packaging Science or Packaging Engineering

- Associate Degree or Higher National Diploma in Packaging Technology

- Master’s Degree in Packaging Engineering or Industrial Design

- Dual BS / MS Packaging Science Degree

- Postgraduate Certificates and Short Courses in Packaging Technology

- Degree Apprenticeship in Packaging or Related Engineering Fields

Bachelor’s Degree In Packaging Science Or Packaging Engineering

A bachelor’s degree in packaging science or packaging engineering teaches material behaviour, structural design and transport testing across a 3 to 4-year academic period. Bachelor’s Degree modules cover materials science, converting processes and regulatory compliance examples such as food-contact rules or recycling standards. Programmes referenced in context, such as Packaging Science BS sequences, include two mandatory co-op blocks and quantitative assessments in compression, seal strength and barrier testing.

Associate Degree Or Higher National Diploma In Packaging Technology

An associate degree or higher national diploma in packaging technology introduces core methods in packaging production, 2D artwork and QA documentation. Associate Degree routes suit students who enter through vocational training, as described in context examples such as graphic design or packaging technology qualifications. Associate Degree modules blend CAD tasks, prototyping and print‑process practice relevant to UK manufacturing.

Master’s Degree In Packaging Engineering Or Industrial Design

A master’s degree in packaging engineering or industrial design expands technical and analytical skills for graduates who plan research or technical‑lead roles. Master’s Degree routes, referenced in context (examples: 2‑year master’s in packaging or industrial design), investigate barrier science, LCA methods and advanced FEA tasks for structural packaging. Master’s Degree modules commonly include research projects linked to material innovation or regulated markets such as pharmaceuticals.

Dual BS / MS Packaging Science Degree

The dual BS / MS packaging science degree aligns undergraduate instruction with postgraduate research tasks. Dual BS / MS courses structure integrated sequences noted in the context (examples: BS / MS dual programme descriptions). Dual BS / MS students complete laboratory-intensive modules, wellness-course requirements typical of U.S. programmes and a research focus that quantifies material performance through standardised testing.

Postgraduate Certificates And Short Courses In Packaging Technology

Postgraduate certificates and short courses in packaging technology create focused routes for working professionals. Postgraduate Certificates appear in context as short-course and continuing‑education models that develop specific skills such as CAD, prototyping or regulatory documentation. Postgraduate Certificates address targeted production topics such as print‑registration accuracy, lamination control or material substitution.

Degree Apprenticeship In Packaging Or Related Engineering Fields

A degree apprenticeship in packaging or related engineering fields combines paid employment with academic study. Degree Apprenticeship structures, described in the context (examples: EPA aggregation and employer‑sponsored routes), evaluate competence through portfolios, workplace evidence and end‑point assessment. Degree Apprenticeship programmes suit UK manufacturers who want trainees to learn test procedures, specification writing and line‑trial participation during live production.

What are the Requirements for A Packaging Degree?

The requirements for a packaging degree include academic qualifications, portfolio evidence, technical aptitude and, in some routes, workplace assessment.

- Academic Entry Criteria

- Subject‑Specific Prerequisites

- Portfolio Or Practical Evidence

- Technical Skill Readiness

- Placement Or Co‑Op Eligibility

- Apprenticeship Assessment Conditions

1.Academic Entry Criteria

Academic entry criteria define the minimum qualifications accepted by packaging programmes. Academic entry criteria usually reference A‑level or equivalent subjects in the UK, with universities expecting grades in science‑based fields for 3‑ or 4‑year bachelor’s routes. Academic entry criteria for master’s degrees reference a prior bachelor’s degree in packaging science, industrial design or a related field, as shown in context examples that include packaging engineering and graphic design degrees.

2. Subject‑Specific Prerequisites

Subject‑specific prerequisites confirm the applicant’s grounding in relevant areas. Subject‑specific prerequisites often include maths, physics or design‑based modules, as these support materials testing, CAD modelling and quantitative tasks described throughout degree structures and BS / MS sequences. Subject‑specific prerequisites for postgraduate courses may also include exposure to barrier science or structural-analysis content.

3. Portfolio Or Practical Evidence

Portfolio or practical evidence demonstrates skill readiness for design‑heavy or technology‑focused packaging degrees. Portfolio or practical evidence may include CAD drawings, printed‑pack examples or prototyping records, consistent with context references where applicants present strong and diverse work samples for design and packaging‑technology pathways. Portfolio or practical evidence often forms part of competitive undergraduate and short‑course admissions.

4. Technical Skill Readiness

Technical skill readiness assesses whether applicants can engage with laboratory modules and production tasks. Technical skill readiness links to software familiarity, such as Illustrator, Photoshop, InDesign or 3D rendering tools described in the context. Technical skill readiness also supports performance testing tasks that quantify compression force, seal strength or OTR values in early modules.

5. Placement Or Co‑Op Eligibility

Placement or co‑op eligibility applies to programmes that embed structured industry blocks. Placement or co‑op eligibility appears in packaging engineering degrees that require two co‑op blocks; applicants confirm availability to complete these blocks during term breaks. Placement or co‑op eligibility strengthens workplace readiness because manufacturers expect evidence of line trials and specification writing.

6. Apprenticeship Assessment Conditions

Apprenticeship assessment conditions govern entry to degree‑apprenticeship pathways. Apprenticeship assessment conditions link academic study to workplace evidence, and EPA criteria aggregate with the degree for the final award, as stated in the context. Apprenticeship assessment conditions require employer sponsorship, on‑site learning capacity and agreement to independent end‑point assessment.

What are the Career Paths After a Packaging Degree?

Career paths after a packaging degree span technical, design, analytical and regulatory roles across manufacturing, logistics and consumer‑goods sectors in the UK. Graduates apply material‑science knowledge, CAD capability and testing skills in production settings.

- Packaging Engineering Roles

- Packaging Design Positions

- Quality and Regulatory Roles

- Supply Chain and Logistics Roles

- Research and Postgraduate Pathways

- Specialist or Cross‑disciplinary Career Routes

Packaging Engineering Roles

Packaging engineering roles use structural calculations, transport‑testing data and material‑selection criteria to create specifications for production. Packaging engineering roles reference co‑op models, BS/MS integrated curricula and the technical skills described in context, such as barrier testing, OTR measurement and compression modelling.

Packaging Design Positions

Packaging design positions use Adobe Creative Suite, CAD tools and prototyping tasks to produce artwork, dielines and 3D forms. Packaging design positions link to education routes described in context, such as graphic design degrees, vocational training in packaging technology and short‑course certification in packaging design.

Quality and Regulatory Roles

Quality and regulatory roles apply testing standards, documentation rules and compliance checks across packaging lines. Quality and regulatory roles use seal‑strength testing, food‑contact compliance and recycling‑label requirements, which match the laboratory tasks and regulatory modules taught across packaging programmes.

Supply Chain and Logistics Roles

Supply‑chain and logistics roles link packaging formats with transport conditions, pallet patterns and warehouse systems. Supply‑chain and logistics roles apply ISTA test results, BCT data and moisture‑control considerations to maintain pack performance throughout distribution.

Research and Postgraduate Pathways

Research and postgraduate pathways follow master’s degrees and doctoral projects described in context texts. Research and postgraduate pathways include polymer development, chemical‑recycling investigation and active‑packaging research using sensor systems or barrier science study.

Specialist or Cross‑disciplinary Career Routes

Specialist or cross‑disciplinary career routes include patent attorney training, if a graduate adds a law degree as described in context. Specialist or cross‑disciplinary career routes also include business‑administration study for engineering‑management posts or industrial‑design progression through higher‑level programmes.

How do Packaging Programmes Develop the Required Technical Skills?

Packaging programmes develop the required technical skills through structured laboratory tasks, design-based assignments, regulated test procedures and workplace practice that mirror conditions in UK manufacturing. Each method builds measurable competence that supports engineering, design or regulatory roles.

- Laboratory testing skills: Students perform tasks in compression, seal‑strength and oxygen‑transmission testing; these tasks align with ISTA transport checks and material‑property measurement used in production settings.

- Materials and process skills: Programmes teach polymer behaviour, fibre‑based substrate analysis and converting steps; examples include flexographic print checks, lamination runs and QA measurements in controlled environments.

- CAD and structural‑design skills: Students create dielines and 3D models using software referenced in context, such as Illustrator, Photoshop, InDesign and 3D rendering tools; outputs include dimensioned drawings and prototype files.

- Regulatory and documentation skills: Modules cover food‑contact rules, recycling‑label requirements and specification writing; students produce controlled documents that mirror those used in UK manufacturing audits.

- Work‑placement and co‑op skills: Degree structures that include two co‑op blocks or year‑in‑industry tasks place students on packing lines, if the applicant meets placement criteria; evidence includes line‑trial observations and validated specifications.

- Apprenticeship assessment skills: Degree‑apprenticeship routes train learners through workplace evidence, EPA aggregation and real process data; assessments validate competence in tasks such as sample preparation or pallet‑pattern checks.

Programmes that combine laboratory work, CAD tasks, regulated documentation and supervised industry practice build the technical capability that employers in the UK test during recruitment.

How to Select the Right Packaging Degree Programme?

To select the right packaging degree programme, focus on academic structure, technical content, entry criteria and progression routes that match manufacturing expectations in the UK. Each step filters programmes by their coursework, assessment style and industry relevance.

- Review degree level: Compare bachelor’s degrees, associate degrees, postgraduate certificates or 2‑year master’s degrees. Bachelor’s routes add materials testing and transport analysis; associate degrees add vocational print‑process tasks; postgraduate routes add research projects.

- Check subject prerequisites: Confirm requirements in maths, physics or design modules, if the programme includes barrier testing, CAD modelling or quantitative tasks. Master’s routes list prior industrial design or packaging science degrees as prerequisites.

- Assess curriculum depth: Examine modules that teach polymer behaviour, fibre‑substrate checks, CAD tasks, seal‑strength testing or regulatory documentation. Programmes with two co‑op blocks or year‑in‑industry tasks teach line‑trial observation and technical documentation.

- Check technical‑skill alignment: Match your skills with course tools. Packaging programmes list Illustrator, Photoshop, InDesign and 3D rendering tools for design tasks. Engineering‑focused programmes list barrier‑testing labs or compression‑test rigs.

- Evaluate placement structure: Identify programmes with co‑op blocks or workplace‑placement periods. Packaging engineering degrees reference two mandatory co‑op blocks; apprenticeships link to employer sponsorship and EPA aggregation.

- Confirm progression routes: Look for paths into BS/MS dual programmes, 2‑year master’s degrees, short courses or professional development tracks. Applicants who plan patent‑attorney work may add a law degree; engineering‑management routes align with business‑administration study.

- Check portfolio requirements: Design‑focused routes list CAD drawings, artwork samples or prototyping evidence. Admissions teams compare colour accuracy, dieline accuracy and production‑ready file structure.

- Match programme outcomes with job goals: Engineering routes prepare graduates for packaging‑engineer roles; design routes suit artwork creation; regulatory modules align with compliance checks across food, cosmetic or pharmaceutical lines.

Programmes that match your prior qualifications, workplace goals and technical interests add structure to long‑term planning. Selection depends on how each degree builds measurable skills across testing, CAD, documentation and workplace practice.