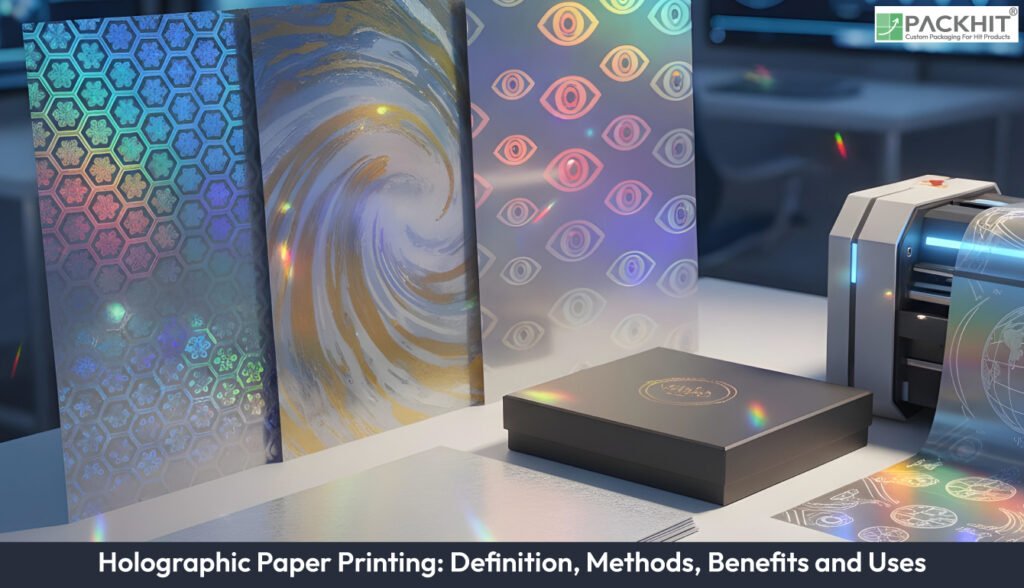

Holographic paper printing places colour on a diffractive sheet that carries embossed micro‑relief, so the surface redirects light across narrow angles and shows depth before any ink sits on it. The process covers direct overprinting, transfer embossing and hot‑foil stamping; each path changes how light moves across the metalised polyester film. Offset, digital, screen and flexographic units record graphics on this surface, and ink thickness controls how much diffraction stays visible. UV‑curable, solvent, water‑based and dye‑based ink families behave differently on the embossed layer; thin films keep colour shift, dense layers hide it. Packaging, labels, cards and short‑run promotional pieces use the optical shift to raise product visibility and add authentication features, if the layout preserves unprinted gaps around key shapes. The method grew from embossed holographic vinyl and holographic sticker workflows, where dye inkjet engines print on metalised polyester film, and clear laminate protects the micro‑relief.

- What is Holographic Paper?

- What is Holographic Paper Printing?

- How Does Holographic Printing Differ from Printing onto Holographic Paper?

- Which Printing Methods are Compatible with Holographic Paper?

- Offset Printing on Holographic Paper

- Digital Printing on Holographic Paper

- Screen Printing on Holographic Paper

- Flexographic Printing on Holographic Paper

- Which Inks work in Holographic Printing?

- What are the Benefits of Holographic Paper Printing?

- Stronger On-Shelf Visibility for Retail Packaging

- Integrated Security Features for Authentication

- Stable Print Performance Across Multiple Processes

- Design Flexibility for Selective Diffraction Zones

- Durable Optical Layer for Handling and Transport

- What are the Uses of Holographic Printing?

What is Holographic Paper?

Holographic paper is a coated sheet that carries a diffractive film created through embossed micro‑relief. Light enters these reliefs and redirects across controlled angles, so the sheet shows depth and colour shift before any printed layer touches the surface. Printed graphics sit above the optical layer and either expose or mask the diffraction, depending on ink density. Unprinted regions keep the strongest shift; dense colour blocks the film.

What is Holographic Paper Printing?

Holographic paper printing places colour onto a substrate that is already holographic. The press deposits UV‑curable, solvent or water‑based inks across the diffractive film, and each layer changes how much holography remains. Offset plates hold detail on pre‑holographic sheets. Digital engines handle short runs. Screen meshes add thicker deposits that suppress diffraction faster. The sequence differs from holographic foil transfer because the holographic layer exists before printing.

How Does Holographic Printing Differ from Printing onto Holographic Paper?

Holographic printing forms a holographic surface by bonding an embossed microstructured film or foil onto paper, plastic or cardboard through heat and pressure. The method includes hot‑foil stamping and thermoplastic embossing, which relocates the metalised polyester film’s pattern onto the substrate and creates the same light‑split behaviour seen in embossed holographic vinyl or sticker film.

Printing onto holographic paper deposits ink onto a sheet that already holds the embossed diffractive layer. The optical pattern is present from the start, and the print method, offset, digital or screen, controls how much of that pattern remains visible. Dye‑based inkjet engines used for holographic vinyl or holographic sticker paper follow the same rules set; thin ink layers keep diffraction, dense areas block it.

Both processes produce angle‑dependent colour shift, yet holographic printing builds the holographic layer first, while printing onto holographic paper applies graphics onto a pre‑made film. Transfer workflows support heat‑and‑press embossing, foil stamping and flexography; overprinting workflows use regular inks that interact with an existing diffractive surface. The distinction matters in packaging production if the brand requires full‑surface holography rather than selective holographic regions.

Which Printing Methods are Compatible with Holographic Paper?

Each printing method that shapes holographic paper output, including offset, digital, screen and flexographic processes are mentioned below:

Offset Printing on Holographic Paper

Offset printing on holographic paper uses plate-based transfer that keeps halftone detail steady and keeps ink spread predictable. Sheetfed or web presses handle long runs with stable colour if operators keep density low enough to stop diffraction loss. Plates hold small text and narrow lines, which helps packaging blocks such as ingredient panels or regulatory notes. Press units load pre-holographic sheets without additional setup, and crews check density strips to track how each ink layer responds to the embossed film. Context from holographic vinyl and holographic sticker work follows the same pattern because embossed metalised polyester film changes light behaviour, and increased density hides the shift faster.

Digital Printing on Holographic Paper

Digital printing on holographic paper uses toner or inkjet engines that place colour on the diffractive layer without plates. Small and mid‑volume runs change quickly because the heads load new data without mechanical setup, if calibration stays aligned to the reflective film. Toner systems keep sharp text, while inkjet heads lay thin deposits that retain partial diffraction. Domestic inkjet printers record dye ink on metalised polyester films, such as holographic vinyl or sticker sheets, and a clear laminate protects the print without affecting the embossed micro‑relief.

Screen Printing on Holographic Paper

Screen printing on holographic paper pushes thick ink films through mesh screens that form dense solids and textured layers. These films block diffraction fast if the layout covers broad panels. Screen units run metallic inks or tactile coatings, and the thicker viscosity fits large packaging components. Small runs gain strong cured layers that resist abrasion, yet the thick deposits cause colour shift in printed zones. The method mirrors embossed metalised polyester film used on holographic vinyl or sticker paper, where heavy deposits sit above the micro‑relief and restrict how light moves across the surface.

Flexographic Printing on Holographic Paper

Flexographic printing for transfer workflows prints graphics and supports microstructure transfer onto non‑holographic stock. Flexible plates apply inks at speed, and transfer film bonds to the surface under heat and pressure. Flexo presses in label plants run this sequence for packaging labels that require holographic patterns, if the substrate cannot accept direct embossing. The process forms a continuous holographic layer that acts like the embossed polyester films used in holographic sticker production.

Which Inks work in Holographic Printing?

Ink systems for holographic printing interact with the embossed film through coverage, opacity and drying behaviour, and the following list identifies the families that define this interaction:

- UV‑curable inks form fast‑set colour layers on embossed coatings and keep adhesion stable on packaging substrates, examples: cartons and labels.

- Solvent‑based inks bond to metalised polyester films and hold colour on transfer‑grade stock, examples: foil‑stamped labels.

- Water‑based inks lay thinner films on diffractive papers and maintain partial holography at low to mid coverage.

- Dye‑based inkjet inks cover holographic vinyl and holographic sticker paper and sit close to the micro‑relief, examples: adhesive vinyl sheets.

- White underprint layers block diffraction across any covered region and support dense graphics that require predictable colour.

- Direct overprinting uses process inks without a white base and keeps partial diffraction if broad solids are avoided.

What are the Benefits of Holographic Paper Printing?

The benefits of holographic printing describe how holographic paper printing changes visibility, security and production behaviour.

Stronger On-Shelf Visibility for Retail Packaging

Holographic paper printing increases on‑shelf visibility because diffractive film redirects light across controlled angles and creates a colour shift that stands out in crowded retail zones. Cartons, sleeves and labels for cosmetics, snacks and accessories use this shift to isolate the pack against flat‑printed products. Embossed metalised polyester film used for holographic vinyl behaves the same way, because micro‑relief on the embossed stock splits white light into narrow bands that move during handling.

Integrated Security Features for Authentication

Holographic paper printing adds anti‑counterfeit traits by forming a fixed embossed pattern that standard CMYK processes cannot copy. Micro‑relief geometry produces diffraction that counterfeit presses cannot match through pigment density. Manufacturers place these patterns on brand seals, closure tabs and warranty cards. Transfer‑grade holographic foil applied with heat and pressure adds extra resistance if the pack uses a bonded layer instead of a pre‑holographic sheet.

Stable Print Performance Across Multiple Processes

Holographic paper printing supports consistent behaviour across offset, digital and screen workflows because the optical layer is fixed before any ink deposition. Offset plates record narrow text on embossed film. Digital toner engines change jobs without plate setup. Screen units form thick films for bold solids. Metalised polyester film used on holographic vinyl and sticker stock follows comparable rules: thin ink preserves diffraction and dense ink blocks it. Brands use this predictability to keep colour and optical zones stable across long runs.

Design Flexibility for Selective Diffraction Zones

Holographic paper printing allows controlled use of diffraction because designers choose which regions remain unprinted and which receive a white underbase. Unprinted areas keep full optical shift; white removes diffraction and stabilises colour. This separation helps packaging teams isolate logos, product names or authentication tabs. Digital and screen presses follow the same layout logic as holographic sticker production, where clear laminate protects the ink but leaves the embossed layer unchanged.

Durable Optical Layer for Handling and Transport

Holographic paper printing maintains optical stability during handling because the embossed film sits below the printed layer. The diffractive pattern resists abrasion on cartons and cards that pass through glueing lines or filling machinery. Holographic vinyl and holographic sticker sheets behave similarly; the embossed micro‑relief continues to diffract after a clear laminate is applied. Packaging suppliers use this durability on folding cartons, hang tags and promotional cards that pass through mechanical systems.

What are the Uses of Holographic Printing?

These uses of holographic printing describe how manufacturers apply diffractive film, ink behaviour and transfer methods across commercial formats, which are explained below:

Artwork and Decorative Printing

The main use is decorative output for artwork that depends on embossed diffraction. Embossed micro‑relief redirects light at controlled angles and records UV‑curable or dye‑based inks without flattening the surface. Limited‑edition art cards, poster accents and small gallery prints use low ink density to keep partial shift across exposed regions. Metalised polyester film used for holographic vinyl follows the same pattern; embossing adjusts surface geometry and creates colour movement before any ink sits on the sheet.

Packaging and Labelling

Holographic paper supports packaging panels that rely on optical patterns to draw attention or confirm product identity. Cosmetic cartons, beverage sleeves and security labels, examples: authentication tabs or serialised seals, use pre‑holographic stock or hot‑transferred holographic foil if a bonded metalised layer is required. Offset, digital or flexographic units apply CMYK on top of the embossed film, and density changes alter how much diffraction stays visible.

Promotional Materials and Short‑Run Items

Short‑run promotional items use holographic paper because digital presses switch artwork without plate changes and record thin deposits on diffractive surfaces. Event badges, holographic sticker giveaways and small merchandising inserts follow the same workflow used for holographic sticker sheets, where dye‑based inkjet engines print onto metalised polyester film and clear laminate shields the micro‑relief without removing the shift.

Cards and Specialised Formats

Cards and specialised formats rely on integral holography if diffraction must cover the whole sheet. Transfer embossing bonds microstructured foil to paper through heat and pressure, and forms a deep optical shift across the panel. Gift cards, brand certificates and limited‑issue vouchers, examples: foil‑sealed passes or loyalty cards, use this process when surface adhesion of the embossed layer is required rather than selective holographic patches.

Security‑Driven Applications in Retail Manufacturing

Holographic paper supports security‑driven uses where embossed geometry forms a pattern that CMYK gradients cannot replicate. High‑value labels, warranty cards and tamper points on folding cartons treat diffraction as an authentication cue. Hot‑foil stamping or thermoplastic embossing forms the diffractive micro‑structure if the base stock starts as plain paper.

Display Cards and Point‑of‑Sale Elements

Display cards and point‑of‑sale elements use embossed holography to isolate foreground graphics under angled lighting. Shelf cards, header boards and small counter displays combine dense solids with unprinted gaps that keep diffraction active. These layouts follow the same behaviour seen in metalised polyester films for holographic vinyl, where the embossed relief redirects light across different angles and increases visual separation in exposed sections.