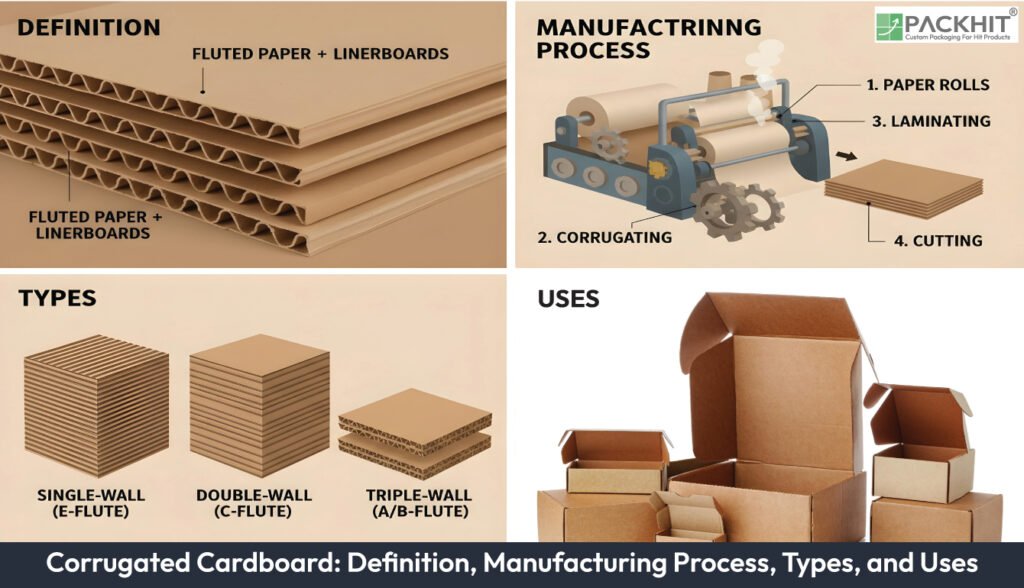

Corrugated cardboard is a multi-layered paperboard made of flat linerboards with a fluted sheet sandwiched between them, which provides strength, rigidity, and shock absorption. The linerboards provide smooth surfaces suitable for printing and load-bearing, while the fluted core cushions impacts and resists bending. Corrugated cardboard balances lightweight handling with structural durability, making it ideal for shipping, storage, retail packaging, and industrial applications. Its versatility allows customisation of wall thickness, flute type, and board grades to meet specific protection, stacking, and branding needs, while remaining fully recyclable and cost-efficient.

- What is Corrugated Cardboard?

- What are the Different Types of Corrugated Cardboard?

- 1. Single-Wall Corrugated Cardboard

- 2. Double-Wall Corrugated Cardboard

- 3. Triple-Wall Corrugated Cardboard

- A-Flute

- B-Flute

- C-Flute

- E-Flute

- F-Flute

- What is the Manufacturing Process of Corrugated Cardboard?

- 1. Flute Formation

- 2. Adhesive Application

- 3. Bonding Linerboards

- 4. Drying and Curing

- 5. Cutting and Scoring

- 6. Production Considerations

- What are the Uses of Corrugated Cardboard?

- What are the Limitations of Corrugated Cardboard?

- How is Corrugated Cardboard Different from Non-Corrugated Paperboard?

What is Corrugated Cardboard?

Corrugated cardboard, also known as corrugated fibreboard, is a multi-layered paperboard composed of at least two flat linerboards with a fluted (wavy) sheet sandwiched between them. The linerboards provide strong, flat surfaces suitable for printing and supporting weight, while the fluted layer adds rigidity, absorbs shocks, and resists bending. Linerboards may be made from virgin kraft, recycled fibres, or a combination of both, which affects the board’s strength and print quality. This three-layer construction provides an ideal balance of lightweight performance for easy handling and shipping, along with sufficient strength and stiffness to allow stacking and protect products during transit.

The key properties of corrugated cardboard are as follows:

- Corrugated cardboard provides high strength and rigidity, allowing stacking and supporting heavy loads without collapsing.

- Corrugated cardboard offers excellent shock absorption, with the fluted layer cushioning impacts and protecting contents during transit.

- Corrugated cardboard remains lightweight, making it easy to handle and transport while maintaining structural integrity.

- Corrugated cardboard features flexible material composition, as it can be made from virgin kraft, recycled fibres, or a combination of both, allowing cost and environmental optimisation.

- Corrugated cardboard provides smooth linerboard surfaces suitable for printing, branding, labelling, and displaying product information.

- Corrugated cardboard resists bending and crushing, with the fluting maintaining the shape of the board under pressure.

- Corrugated cardboard is highly versatile, allowing customisation of thickness, flute type, and board grades for specific packaging needs.

- Corrugated cardboard supports sustainability, being fully recyclable and often made from eco-friendly materials.

What are the Different Types of Corrugated Cardboard?

Corrugated cardboard is categorised based on the number of walls and the fluted profiles.

The types of corrugated cardboard, based on the number of walls, are given below:

1. Single-Wall Corrugated Cardboard

Single-wall corrugated cardboard is the most common type, consisting of one fluted layer between two linerboards. It is lightweight and provides good protection for most standard packaging needs, such as shipping boxes and retail packaging.

2. Double-Wall Corrugated Cardboard

Double-wall corrugated cardboard has two fluted layers separated by three linerboards, offering increased strength and rigidity. They are ideal for heavier or fragile products and for long-distance shipping.

3. Triple-Wall Corrugated Cardboard

Triple-wall corrugated cardboard contains three fluted layers and four linerboards, providing maximum load-bearing capacity. They are used for extremely heavy items, industrial goods, or applications requiring superior stacking strength.

Common corrugated cardboard flute profiles include the following:

A-Flute

A flute is the thickest common flute, providing excellent cushioning and impact resistance. Its height gives superior protection for fragile or heavy items during shipping. Because of its thickness, A-flute adds more overall board height and is slightly less suited for printing fine graphics.

B-Flute

B-flute is thinner than A-flute, offering good stacking strength while providing moderate cushioning. It is commonly used for retail packaging and smaller boxes that require a smooth surface for printing. B-flute strikes a balance between strength and compactness, making it versatile for many applications.

C-Flute

C-flute is the most widely used flute type, combining good cushioning with decent stacking strength. Its medium thickness makes it suitable for shipping a wide variety of products, from electronics to food items. C-flute also performs well with printed graphics, maintaining a relatively smooth surface.

E-Flute

E-flute is very thin, offering minimal cushioning but a very smooth surface for high-quality printing. It is ideal for retail packaging, folding cartons, and product presentation where appearance is important. E-flute is lightweight and compact, making it perfect for smaller boxes or inserts.

F-Flute

F-flute is the thinnest common flute, providing excellent surface smoothness for detailed graphics and premium packaging. Its cushioning is minimal, so it is generally used for small, lightweight items or protective inserts. F-flute is often chosen when print quality and aesthetic appeal are the main priorities.

The table below summarises common flute types, thicknesses, and typical uses.

| Flute Type | Approx. Thickness (mm) | Approx. Thickness (cm) | Typical Use |

| A-Flute | 4.7 – 5.0 mm | 0.47 – 0.50 cm | Heavy or fragile items, high cushioning |

| B-Flute | 2.5 – 3.0 mm | 0.25 – 0.30 cm | Die-cut boxes, retail packaging, good print surface |

| C-Flute | 3.5 – 4.0 mm | 0.35 – 0.40 cm | Standard shipping boxes |

| E-Flute | 1.0 – 1.8 mm | 0.10 – 0.18 cm | Retail packaging, high-resolution printing |

| F-Flute | 0.7 – 1.0 mm | 0.07 – 0.10 cm | Small retail boxes, premium packaging |

The table above shows how flute thickness ranges from thicker profiles like A, B, and C, which offer stronger cushioning and are ideal for shipping and heavier items, to thinner profiles like E and F, which provide a smoother surface for retail packaging and premium printing. These thickness variations help manufacturers choose the right corrugated board type based on the level of protection, rigidity, and print quality required.

What is the Manufacturing Process of Corrugated Cardboard?

The manufacturing process of corrugated cardboard involves the following key steps:

- Flute Formation

- Adhesive Application

- Bonding Linerboards

- Drying and Curing

- Cutting and Scoring

- Production Considerations

1. Flute Formation

The corrugating medium is fed through heated rollers that shape it into wavy flutes. These flutes provide the corrugated board with rigidity, strength, and shock absorption, which helps protect products during transit. The size and profile of the flutes also influence cushioning and stacking performance, making this step critical for board performance.

2. Adhesive Application

A water-based starch adhesive is applied to the peaks of the flutes to bond them to the linerboards. This adhesive ensures that the corrugated structure maintains its integrity under pressure and during handling. The choice and even application of adhesive directly affect the board’s durability and long-term performance.

3. Bonding Linerboards

Flat linerboards are pressed onto the glued flutes to form a continuous corrugated sheet. For stronger boards, multiple layers of liners and flutes can be laminated together, creating double-wall or triple-wall boards. This step determines the overall thickness, strength, and load-bearing capacity of the final product.

4. Drying and Curing

The adhesive is dried and cured under controlled temperature and humidity conditions to ensure a strong and permanent bond. Proper drying prevents delamination and maintains the structural integrity of the board. This step is crucial for producing a reliable board that can withstand stacking, handling, and shipping stresses.

5. Cutting and Scoring

The continuous corrugated sheet is cut to the required width and scored to create fold lines for box formation. These fold lines allow easy assembly of boxes into their final shape without damaging the structure. Accurate cutting and scoring are essential for uniformity, precise assembly, and optimal packaging efficiency.

6. Production Considerations

Increasing the number of liner and flute layers improves crush resistance and load-bearing capacity, making the board suitable for heavier or more fragile items. The type of adhesive and quality of bonding are critical to ensure durability during handling, stacking, and transport. Single-wall boards are generally used for light loads, while double- or triple-wall boards are preferred for heavy-duty or long-distance shipping applications.

What are the Uses of Corrugated Cardboard?

Corrugated cardboard is used across many industries for packaging, protection, and storage. In shipping and logistics, corrugated cardboard serves as the primary packaging solution for transporting a wide range of goods. It is lightweight yet strong, helping to reduce shipping costs while protecting products from impacts, drops, and stacking pressures. The fluted structure acts as a natural shock absorber, cushioning fragile items such as electronics, glassware, and food products. This ensures that goods arrive in excellent condition, reducing breakage, returns, and overall costs for businesses. Corrugated cardboard is also highly adaptable and can be customised for product fit, combined with inserts, and printed with branding or handling instructions. Because of these qualities, it is widely used in e-commerce, courier services, and global supply chains.

Corrugated cardboard has numerous non-transit uses. In retail, it is used for product boxes, point-of-sale (POS) displays, and branded packaging that combine durability with attractive design. It is also widely used for storage solutions, including home, office, and warehouse boxes, helping to organise and protect items efficiently. These non-shipping uses demonstrate the material’s versatility and make it a popular choice across multiple sectors.

What are the Limitations of Corrugated Cardboard?

The limitations of corrugated cardboard include:

- Moisture Sensitivity: It can weaken, warp, or collapse when exposed to water or high humidity.

- Limited Reusability: Repeated use can reduce its strength, even though it is recyclable.

- Surface Quality: The fluted surface is not perfectly smooth, making high-quality printing more difficult compared to flat paperboard.

- Bulkiness: It takes up more storage space than flat boards when not in use.

- Weight Limits: Standard single-wall corrugated may not support very heavy or concentrated loads.

- Storage Requirements: Must be stored flat and dry to maintain structural integrity and prevent bending.

How is Corrugated Cardboard Different from Non-Corrugated Paperboard?

Corrugated cardboard differs from non-corrugated paperboard mainly because it has a fluted core between flat linerboards. This structure provides better cushioning, higher compression resistance, and greater bending stiffness compared to flat paperboard of the same weight. Non-corrugated (flat) paperboard offers a smooth, uniform surface and is preferred where thinness and appearance are more important. Corrugated cardboard is used when protection, structural strength, and durability during shipping or handling are the main priorities.