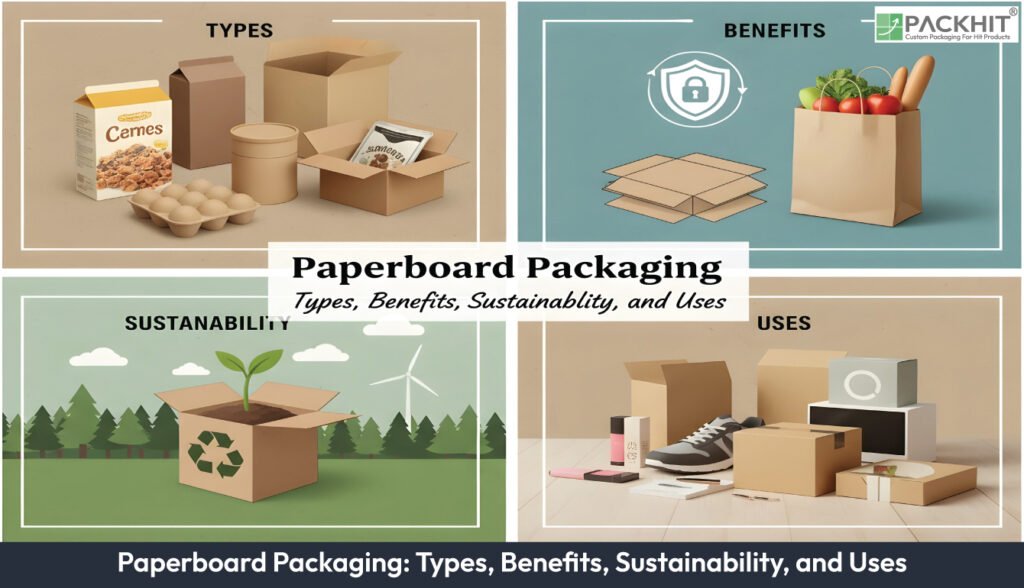

Paperboard packaging combines versatility, strength, and sustainability, becoming suitable for a wide range of industries. Types of paperboard packaging grades offer varying levels of stiffness, printability, and recycled content to meet different functional requirements. The benefits of paperboard packaging enhance performance, efficiency, and sustainability across applications, while emerging trends and key material considerations continue to shape the capabilities and selection of cartonboard packaging.

- What is Paperboard Packaging?

- How is Paperboard Manufactured?

- What are the Types of Paperboard Grades Used for Packaging?

- 1. Solid Bleached Sulfate (SBS)

- 2. Folding Box Board (FBB)

- 3. Coated Unbleached Kraft (CUK)

- 4. Coated Recycled Board (CRB)

- 5. Clay Coated News Backboard (CCNB)

- 6. Natural Kraft (SUS)

- 7. Chipboard

- What are the Benefits of Paperboard Packaging?

- Strong Product Protection

- Lightweight and Efficient Material

- Eye-Catching Brand Presentation

- Cost-Effective Packaging

- Environmentally Friendly

- Flexible Design and Conversion

- How is Paperboard Considered Sustainable?

- Applications of Paperboard Packaging

- Food and Beverage Packaging

- Healthcare and Pharmaceutical Packs

- Beauty and Personal Care Boxes

- Wine and Alcohol Packaging

- Footwear and Apparel Boxes

- Electronics and Small Appliance Cartons

- Downstream Conversion and Supply

- How is Paperboard Measured and Specified?

- How Does Paperboard Differ from Related Packaging Materials?

- How to Choose Paperboard for Product Packaging?

- What Are the Limits and Challenges of Paperboard Packaging?

- What are Emerging Trends in Paperboard Packaging?

What is Paperboard Packaging?

Paperboard packaging is a sheet material specified for product containment and presentation. Paper-based board is thicker than ordinary paper yet thinner than corrugated materials. Paperboard is formed from wood pulp derived from trees and may contain recycled paper fibres. Single or multi-layer paperboards provide structure, with multi-layer constructions adding extra strength. Longer fibres increase stiffness and tear resistance in paperboard packaging as compared to regular paper. Minimal or no mineral fillers maintain bulk and enhance print quality.

How is Paperboard Manufactured?

Manufacturing of paperboard starts with wood pulp and recycled fibres forming a base slurry. Wet fibres are layered and formed into sheets, which are produced as single‑ply or multi‑ply laminates to achieve the desired stiffness, bulk, and print surface. Sheets are dried, calendered, and, if needed, coated for gloss, print quality, or barrier properties. Finished sheets are supplied to converters for die‑cutting, folding, and glueing into cartons and packaging. Long fibres enhance strength, while minimal fillers preserve bulk and appearance. Production is scalable for high‑volume supply chains.

What are the Types of Paperboard Grades Used for Packaging?

Four major commercial grades commonly appear in procurement and design specifications, including Solid Bleached Sulfate (SBS), Folding Box Board (FBB), Coated Unbleached Kraft (CUK), and Coated Recycled Board (CRB). Each paperboard grade represents a different combination of base fibres, surface treatment and functional role.

1. Solid Bleached Sulfate (SBS)

SBS is a bleached chemical pulp board supplied as white sheets, used for printing or applications needing clean surfaces or food contact safety. Solid Bleached Sulfate is recyclable, though bleached fibres and coatings affect the lifecycle. Select SBS when a white, printable surface and food compatibility are key. A dense fibre network gives SBS consistent rigidity that supports detailed surface graphics in sectors such as confectionery and cosmetics.

2. Folding Box Board (FBB)

Folding Box Board is usually a multi‑ply construction combining different pulp layers, providing bulk and stiffness while keeping the weight moderate. FBB is commonly used for folding cartons requiring stiffness and light weight, such as cereal boxes, pharmaceutical cartons, and other retail packs. A layered core produces a favourable stiffness‑to‑weight ratio that suits retail cartons with printed faces on supermarket shelves.

3. Coated Unbleached Kraft (CUK)

Coated Unbleached Kraft (CUK) uses unbleached kraft as the base with a surface coating for printing and moisture control. CUK is selected when strength and a printable or coated surface are needed. Choose CUK when an unbleached appearance and structural durability are essential for the packaging design. A long‑fibre base sheet adds tear resistance that supports multipack carriers for beverages.

4. Coated Recycled Board (CRB)

Coated Recycled Board (CRB) combines recycled fibres with surface coatings for printability and durability. CRB balances recycled content, cost, and performance, though whiteness and stiffness are lower than virgin boards. Use Coated Recycled Board when recycled content is the main priority. A recycled furnish reduces virgin pulp demand in applications such as household goods cartons.

5. Clay Coated News Backboard (CCNB)

Clay Coated News Backboard (CCNB) is a recycled board made from newsprint with a clay-coated top surface to enhance smoothness and printability. CCNB is commonly used for folding cartons and packaging where cost-effective printing and moderate stiffness are needed. A newsprint base introduces fibre variability that supports economical runs for lightweight consumer goods.

6. Natural Kraft (SUS)

Natural Kraft (SUS) is an unbleached, strong kraft board made from long fibres, valued for durability and structural strength. SUS is commonly used for packaging that requires high load‑bearing capacity and a natural, brown appearance. A dense kraft matrix withstands compression loads found in heavy food multipacks.

7. Chipboard

Chipboard, a single‑ply paperboard, is commonly used for backing, inner supports, and basic retail boxes. Cost‑effective performance suits low‑presentation applications, such as inner packers and simple consumer goods boxes. A recycled fibre furnish keeps chipboard pricing stable in sectors producing stationery backers and low‑compression inserts.

What are the Benefits of Paperboard Packaging?

Paperboard packaging delivers strength, versatility, and sustainability, with its main benefits outlined below:

Strong Product Protection

Paperboard keeps products safe during handling and transit because rigid fibre layers restrict deformation under load. Carton strength links to paperboard’s classification as a type of cardboard, which supports stacked goods in sectors such as toys, electronics, and household items.

Lightweight and Efficient Material

Lighter weight than metal or glass reduces transport mass and lowers vehicle fuel usage. Reduced material mass aligns with carton-box in manufacturing, where lighter substrates shorten loading times for fulfilment teams.

Eye-Catching Brand Presentation

Smooth surfaces and printable coatings create sharp text, strong colour, and consistent finishes. Graphic quality gains from paperboard’s rigidity, as rigid sheets hold register more reliably than thin papers used in basic cartons.

Cost-Effective Packaging

High-volume production creates predictable per‑unit pricing across procurement cycles. Cost behaviour varies with thickness and fibre grade, as some paperboard grades sit close to corrugated prices even when used for smaller consumer cartons.

Environmentally Friendly

Widely recyclable fibres and certified pulp support sustainability. Recycling familiarity rises because paperboard forms part of the broader cardboard group processed in most municipal facilities.

Flexible Design and Conversion

Die‑cutting, folding, glueing, and coating allow varied structural forms without compromising functional strength. Conversion flexibility expands because converters run paperboard and corrugated materials on related machinery when carton volumes rise.

How is Paperboard Considered Sustainable?

Paperboard is recyclable and biodegradable, and the recycling route depends on local waste systems and any coatings or laminates on the board. Paperboards use recycled paper fibres. The recycled content cuts virgin pulp use and reduces landfill input. Many mills source pulp from certified forests through chain‑of‑custody schemes that track fibre origin. Bleached, unbleached and recycled variants carry different environmental traits, and coatings or laminates can block reprocessing. Paperboard supports circular systems when collection, pulping and remanufacture operate in the region, and packaging papers and boards form a large share of global paper output. Coatings and adhesives that add moisture or grease resistance can reduce recyclability and must fit local end‑of‑life rules. Paperboard sits within the broader cardboard group used for carton boxes, and this link increases recycling familiarity for items such as folding cartons, boxboard units and corrugated formats. According to the GOV.UK, the recycling rate for paper and cardboard packaging rose to 74.3% in 2024.

Applications of Paperboard Packaging

Paper-based packaging is used across industries for its versatility and eco-friendly benefits, supporting a wide range of applications. Key applications include:

Food and Beverage Packaging

Used for folding cartons, printed boxes, and foodservice trays. Paperboard in this category supports grease‑resistant coatings if barrier performance is needed and keeps weight low for chilled or shelf‑stable formats.

Healthcare and Pharmaceutical Packs

Supports lightweight, clean, and printable packaging for medical and OTC products. Paperboard grades in this sector maintain lot‑code legibility and permit tamper‑evident features for regulated items such as blister card sleeves.

Beauty and Personal Care Boxes

Provides high‑quality print surfaces for branded retail packaging. Paperboard holds embossed or foil‑stamped artwork that increases shelf clarity for fragrance cartons and skincare units.

Wine and Alcohol Packaging

Serves as a primary material in many wine pack systems and premium box formats. Multi‑ply boards resist tear loads in bottle multipacks and support dark‑ink palettes for spirit cartons.

Footwear and Apparel Boxes

Commonly used for shoeboxes and small retail boxes across fashion categories. Paperboard maintains structural shape during stacking in storerooms and supports colour branding for seasonal lines.

Electronics and Small Appliance Cartons

Used for mobile accessories, handheld devices, and small household appliances. Paperboard keeps inserts stable for chargers or cables and reduces unnecessary plastic moulds if the product’s weight is moderate.

Downstream Conversion and Supply

Delivered as sheets to converters who die‑cut, crease, fold, and glue the board; folding cartons are shipped flat to reduce transport and storage space. Paperboard simplifies print‑run planning for converters because sheet callipers remain consistent across procurement batches.

How is Paperboard Measured and Specified?

The specification of paperboard packaging begins with grammage and thickness. Paperboard grammage is measured in g/m², typically following ISO (International Organization for Standardization) standards above 200 g/m² or CEPI (Confederation of European Paper Industries) standards above 220 g/m² for contracts. Thickness ranges from 14 to 24 points (0.014–0.024 inches), typically in 2-point increments. Paperboard is delivered as sheets or reels for die‑cutting, folding, and glueing by converters.

How Does Paperboard Differ from Related Packaging Materials?

Paperboard differs from corrugated, rigid substrates, and plastics in structure, cost behaviour, and end‑of‑life traits, as shown in the table below:

| Material | Primary Use | Structural Behaviour | Cost Pattern | End‑of‑Life Traits |

| Paperboard | Retail cartons, folding boxes, printed packs | Holds colour accuracy and text precision for display packs | Stable per‑unit costs in high‑volume runs | Recyclable and biodegradable under common municipal systems |

| Corrugated Board | Transport cartons, storage units, transit packaging | Higher edge‑crush resistance for stacked loads | Varies with flute type and liner weight | Recyclable via cardboard streams |

| Rigid Box Substrates | Set up boxes and heavier presentation packs | Denser sheet structures add tactile stiffness | Higher cost due to assembly steps and board weight | Recycling influenced by wraps, laminates, and adhesives |

| Plastics | Packs needing durable moisture barriers | Stable moisture resistance in chilled or wet use | Dependent on resin grade and forming method | Recycling is limited; emissions increase at disposal |

Packaging material selection depends on balancing barrier properties, durability, and sustainability.

How to Choose Paperboard for Product Packaging?

Paperboard selection involves matching the material’s properties to the product’s functional, regulatory, and sustainability requirements.

- Match requirements to attributes: Start by aligning functional needs with paperboard properties.

- Structural factors: Consider grammage and thickness for strength, and ply configuration for stiffness.

- Surface and print: Evaluate surface finish for printing quality and brand presentation.

- Sustainability: Check recycled content to meet environmental targets.

- Coatings: Assess type for barrier performance and recyclability; verify compatibility with local recycling systems.

- Food safety: Confirm regulatory compliance and food-contact suitability where needed.

- Supply and certification: Request chain-of-custody documentation for forest-sourced or recycled fibres.

- Grade selection: SBS for bleached, white surfaces with food compatibility. FBB for folding-carton stiffness and efficient flat shipping. CUK for unbleached strength with a coated surface. CRB when recycled content is the main priority.

What Are the Limits and Challenges of Paperboard Packaging?

Despite its advantages, paperboard packaging faces the following challenges that affect performance, durability, recyclability, and suitability for certain applications.

- Limited moisture resistance occurs because paperboard does not resist water or grease well, and polymer or wax coatings used for protection may make recycling harder.

- Weakness under heavy loads or outdoor use means very heavy items or prolonged outdoor exposure require stronger materials, such as corrugated board.

- Recycling complications arise because colours, inks, adhesives, and laminates can affect recycling and impact reprocessing.

- Balancing cost with premium appearance is a challenge because rigid set-up boxes feel premium, while regular paperboard is more cost-efficient.

What are Emerging Trends in Paperboard Packaging?

New coating technologies are extending barrier performance while remaining compatible with recycling, making coating chemistry important for end-of-life outcomes. Digital printing supports fast customisation by reducing setup time and enabling quick variant changes. Intelligent packaging is developing as RFID (Radio-Frequency Identification) tags are tested in paperboard to enhance inventory tracking and traceability, useful when distribution or returns require detailed monitoring. Sustainability efforts focus on higher recycled content and certified sourcing, and some suppliers now produce multi-ply paperboard down to 160 g/m² when design permits weight reduction without losing performance.