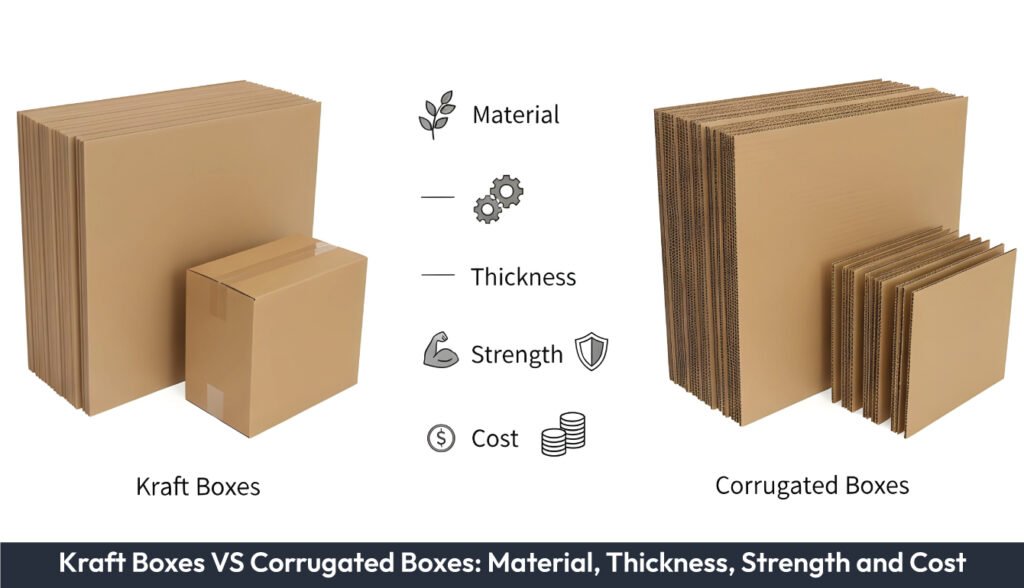

Kraft boxes and corrugated boxes differ primarily in terms of material composition, structural strength, and intended packaging performance. Kraft boxes use a single layer of strong kraft paper, being light, clean, and suitable for small retail items or food products. Strength stays moderate unless an extra corrugated layer is added. Corrugated boxes utilise fluted cardboard with multiple layers, giving high strength for shipping, storage, and heavier products. Kraft boxes usually cost less, while corrugated boxes cost more because they offer stronger protection. Both kraft and corrugated boxes are recyclable, with kraft often viewed as the more eco-friendly choice.

- What are the Differences Between Kraft Boxes and Corrugated Boxes?

- 1. Material and Construction

- 2. Thickness and Formation

- 3. Strength and Protection

- 4. Cost Behaviour

- 5. Recyclability and Environmental Considerations

- 6. Surface Quality and Printability

- How Do Corrugated and Kraft Boxes Differ in Production and Supply Chain?

- Which Box Type to Choose: Kraft vs Corrugated?

What are the Differences Between Kraft Boxes and Corrugated Boxes?

Kraft and corrugated boxes differ in structure, surface, and purpose. Kraft offers a smooth printable surface for presentation and branding, while corrugated provides layered strength with a fluted core for protection and stacking. Both are recyclable and serve as packaging and shipping materials, but their specifications vary. Kraft emphasises print quality, corrugated emphasises mechanical protection and cost-efficiency.

The six key differences between kraft boxes and corrugated boxes can be summarised as follows:

1. Material and Construction

Kraft boxes are made from single-sheet kraft paper, providing a smooth, printable surface ideal for presentation and branding. The construction focuses on consumer-facing packaging, maintaining visual appeal while supporting moderate protection. Corrugated boxes consist of multi-layered panels with a fluted core bonded between liners, offering structural strength for transit, stacking, and shock absorption. The layered design prioritises mechanical protection and load distribution.

2. Thickness and Formation

Thickness in kraft boxes comes from paperboard calliper and fibre bonding. Firm panels crease cleanly, supporting complex shapes and small-format cartons while maintaining a smooth surface for printing. Corrugated boxes achieve thickness through the fluted medium and liner layers. Single-, double-, or triple-wall constructions adjust crush resistance and shock absorption, enabling the boxes to withstand heavier loads and repeated handling.

3. Strength and Protection

Kraft boxes provide moderate strength suitable for light transit and shelf display, preserving the printed surface and visual quality. Corrugated boxes deliver high compressive strength and impact resistance, with the fluted structure distributing loads and absorbing shocks during storage and shipping.

4. Cost Behaviour

Cost variation comes from material grade, board thickness, conversion steps, print complexity, finishing work, and production scale. Kraft boxes tend to cost more when surface quality, coatings, or short-run printing dominate the specification. Corrugated boxes gain cost efficiency from continuous corrugator production, recycled fibre content, and standardised dies, with expenses rising only when multi-wall builds or retail-grade litho-lamination are required.

5. Recyclability and Environmental Considerations

Both corrugated and kraft boxes support recycling and circular waste management when handled properly. Kraft boxes are fully biodegradable and particularly suited for eco-friendly packaging. Corrugated boxes, often made from recycled fibres, offer durability that extends the lifecycle and supports sustainable shipping practices. Design choices such as adhesives, laminates, or coatings can affect recyclability for both materials.

6. Surface Quality and Printability

Kraft boxes feature a smooth surface that supports high-fidelity graphics, vibrant colours, and premium finishes, with coatings enhancing print depth and tactile appeal. Corrugated boxes accept flexographic or litho-lamination printing, with quality improved by coated liners or post-conversion printing, suitable for logos and handling marks.

How Do Corrugated and Kraft Boxes Differ in Production and Supply Chain?

Corrugated and kraft boxes move through different production steps that affect lead times, minimum order quantities, and inventory management. Corrugated boxes run on high-speed corrugator lines that create the fluted board before the sheets are cut, printed, folded, or glued. Kraft boxes rely on sheet-fed printing, die-cutting, creasing, and folding, with optional varnish or coating to improve surface quality. Storage and logistics also differ. Corrugated blanks stack tightly and store in large counts without wasted space, while custom‑printed kraft cartons take longer to produce and use higher minimum order counts because the unbleached kraft stock and print steps run on slower sheet‑fed machines.

Which Box Type to Choose: Kraft vs Corrugated?

The table below compares kraft boxes and corrugated boxes, their uses, ideal applications, and advantages to help businesses select packaging that prioritises strength, protection, presentation, and print quality for shipping and retail display.

| Box Type | Primary Use | When to Choose | Examples |

|---|---|---|---|

| Corrugated Box | Transit protection and bulk handling | When strength, stacking, and impact protection matter, good for long transit, palletisation, or multiple handling cycles | Shipping cartons, mailers, bulk containers (electronics, industrial parts, subscription boxes) |

| Kraft Box | Presentation and high-quality printing | When surface quality, print detail, and consumer-facing appearance are important, ideal for retail, unboxing, or food-grade packaging | Product cartons, artisanal food boxes, boutique apparel packaging |

Kraft stock uses unbleached pulp with firm fibres, while corrugated board uses a fluted core that adds crush resistance. Selection depends on whether printed presentation or mechanical strength drives the packaging requirement.