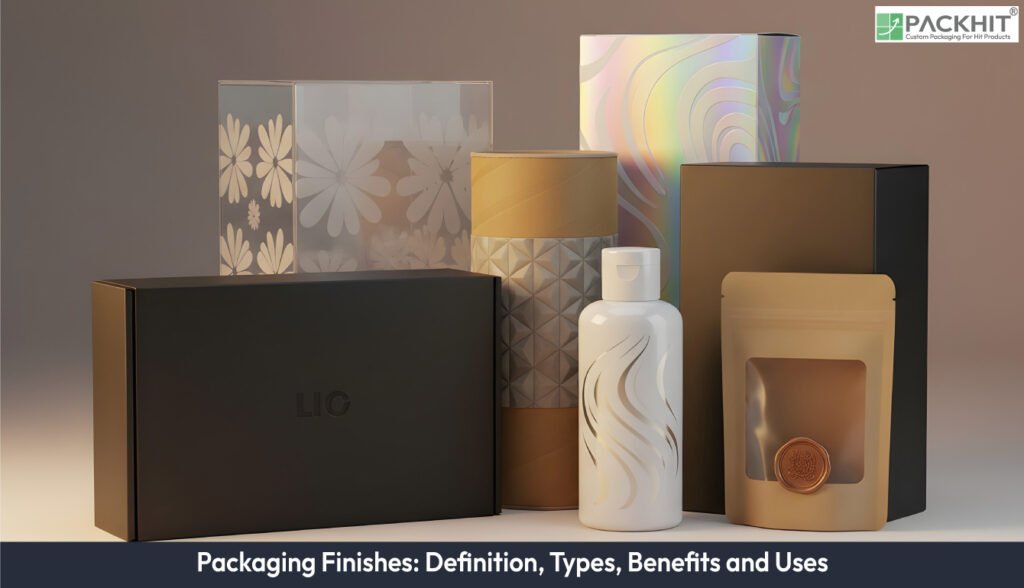

Packaging finishes improve the appearance, feel, and functionality of packaging while reinforcing brand identity and protecting the product. A range of visual and tactile effects, from gloss and matte coatings to embossing, foil stamping, and soft-touch finishes, allows brands to create a distinctive shelf presence and enhance consumer experience. The selection of packaging finishes depends on factors such as substrate type, printing method, product requirements, and distribution conditions. Well-chosen finishes not only increase durability and resistance to wear but also support sustainability goals through eco-friendly options. By carefully integrating finishes into packaging design, product appeal, ensuring performance, and maintaining high-quality standards across industries, including food, cosmetics, electronics, and pharmaceuticals.

- What are Packaging Finishes?

- Why Packaging Finishes Matter?

- What Different Types of Packaging Finishes Exist?

- 1. Matte Finishes

- 2. Gloss Finishes

- 3. Soft‑Touch Coatings

- 4. UV (Ultraviolet) Coatings

- 5. Laminations

- 6. Foil Stamping

- 7. Embossing and Debossing

- 8. Aqueous (Water‑Based) Varnishes

- 9. Holographic and Metallic Finishes

- 10. Spot Coatings and Texture Printing

- What Benefits do Packaging Finishes Provide?

- Protective Surface Protection

- Enhanced Optical Control

- Distinctive Tactile Differentiation

- Strong Brand Distinction

- Sustainable Environmental Benefits

- Where are Packaging Finishes Used Across Different Industries?

- Finishes for Beauty and Personal-Care Packaging

- Finishes for Paperboard and Rigid Box

- Finishes for Flexible Packaging

- Finishes for Holographic Foils

- What Sustainability Considerations Affect Packaging Finishes?

- How are Packaging Finishes Combined and Applied?

- What Practical Constraints Affect Packaging Finishes?

- What are the Key Factors and Quality Checks for Selecting Packaging Finishes?

- What are the Current Trends in Packaging Finishes?

What are Packaging Finishes?

Packaging finishes are targeted treatments applied to a printed or unprinted substrate to modify appearance, feel and resistance to environmental or mechanical stress. Printing enhancements include coatings, film lamination, metallic transfers and mechanical forming processes that alter surface reflection, friction, puncture resistance and barrier behaviour. Typical functions of printing finishes are visual modulation (e.g. reduced specular reflection), surface protection (scratch and moisture resistance), tactile signalling (velvet or embossed textures) and brand differentiation. Substrates commonly finished include folding carton paperboard, rigid box board and polymer films used in flexible packaging.

Why Packaging Finishes Matter?

Packaging finishes matter because they shape how customers judge quality by adding defined visual and tactile cues that affect handling, durability, and shelf‑level recognition. Precision coatings, foils, or textured surfaces guide quick product comparisons in crowded aisles and anchor brand interpretation during first contact. A finish also controls how light hits artwork, which shifts colour density, edge definition, and perceived print sharpness. Retail conditions place stress on substrates during stacking and transit, and a suitable finish limits surface abrasion that might obscure key information. Finishes influence grip and stiffness, which alter the way cartons bend or resist scuffing during manual handling.

What Different Types of Packaging Finishes Exist?

Packaging finishes fall into several categories, including varnishes and coatings, film laminates, metallic foils, mechanical textures and speciality films. Common examples of printing finishes include matte, glossy, soft-touch, ultraviolet-cured coatings (UV), lamination (film-based), foil stamping (metallic and holographic), embossing/debossing, aqueous varnishes, spot coatings and biodegradable laminates.

1. Matte Finishes

Matte finishes produce a low-gloss, low-reflection surface that mutes highlights and reduces glare. Matte finishes are achieved with matte aqueous varnish or matte film lamination and typically have lower perceived colour saturation compared with gloss. The matte finishes are used in folding cartons for consumer goods and printed sleeves where a subdued visual tone is required. Matte films and varnishes change light scattering and therefore require proofing to confirm colour targets.

2. Gloss Finishes

Gloss finishes increase surface reflectivity and apparent colour density, and are implemented by gloss varnishes, gloss lamination films [BOPP (biaxially oriented polypropylene) or PET (polyethene terephthalate)] or UV gloss coatings. Gloss improves wet-look appearance and eases surface cleaning but increases specular highlights under store lighting. Retouch proofs are advisable in gloss finishes to avoid unexpected glare on photographic art.

3. Soft‑Touch Coatings

Soft-touch coatings create a low-sheen, velvety surface with increased friction and a tactile ‘suede’ feel. Applied as a specialised polymer coating or lamination, soft-touch reduces surface slip and raises perceived value for categories such as cosmetics and premium consumer electronics packaging. Process control is required to avoid adhesion failures on oily or waxy inks.

4. UV (Ultraviolet) Coatings

UV coatings cure rapidly under ultraviolet lamps to form a hard, abrasion-resistant surface with selectable gloss levels. Flood UV covers entire panels; spot UV applies glossy relief to selected areas for contrast against a matte field. UV curing requires in-line or offline UV curing stations and appropriate ink chemistry for adhesion.

5. Laminations

Laminations bond a polymer film to the substrate to add moisture and abrasion resistance and to modify surface finish. Film options include polypropylene and polyester in gloss or matt variants, and newer biodegradable film options. Lamination affects fold behaviour and glue lines; converting plans must account for film thickness and laminating adhesive properties.

6. Foil Stamping

Foil stamping transfers metallic or pigmented foil to a surface using heat and pressure or in-line cold-foil processes to create metallic visual effects. Hot-foil stamping uses a heated die and is commonly combined with embossing; cold-foil may be applied in-line with flexographic processes. Foil selection affects recyclability and may require separate tooling, which impacts setup cost and lead time.

7. Embossing and Debossing

Embossing raises a design element above the surrounding surface. Debossing presses it below the surface plane. Achieved with matched male and female dies. Both processes add tactile topography and cast shadow, which improves legibility and perceived tactile complexity. Embossing and debossing are frequently paired with foil stamping for metallic relief.

8. Aqueous (Water‑Based) Varnishes

Water-based varnishes provide protective coating with variable gloss and lower volatile organic compound emissions than solvent-based alternatives. Applied in line or offline, aqueous varnishes offer moderate protection against scuffs and can serve as a lower-impact protective layer. They are compatible with many paperboard substrates and are increasingly used where solvent restrictions apply.

9. Holographic and Metallic Finishes

Holographic finishes use diffractive films or metallised foils to produce rainbow diffraction patterns for visual emphasis and security. Metallic finishes are implemented via film lamination or specialised foil stamping and are common for anti-counterfeiting measures and high-visibility promotional packaging.

10. Spot Coatings and Texture Printing

Spot coatings confine gloss, satin or textured coating to selected areas to create visual and tactile contrast. Texture printing and spot coatings require separate artwork layers and accurate registration. The examples of spot coatings include a glossy logo on a matte panel and, tactile texture around product imagery.

What Benefits do Packaging Finishes Provide?

The benefits of packaging finishes go beyond aesthetics, improving protection, functionality, and brand impact. The key benefits include:

Protective Surface Protection

Protective surface protection provided by packaging finishes helps safeguard packages against moisture, scratches, and fading. Laminations and ultraviolet coatings strengthen the packaging surface, ensuring that products maintain their appearance during shipping, handling, and storage.

Enhanced Optical Control

Enhanced optical control is achieved through finishes that adjust gloss, matte, and colour density, as well as reduce glare. Matte and gloss finishes modify how light interacts with the surface, enhancing visual appeal and making printed designs more vibrant or subdued according to design needs.

Distinctive Tactile Differentiation

Distinctive tactile differentiation comes from finishes that add texture and feel to packaging. Soft-touch coatings and embossing create sensory cues that influence how consumers perceive and handle the product, adding a premium or distinctive touch.

Strong Brand Distinction

Strong brand distinction is enhanced by finishes that reinforce the visual identity of the product. Foil stamping, spot coatings, and textured surfaces help packaging stand out on shelves, improving recognition and perceived value.

Sustainable Environmental Benefits

Sustainable environmental benefits in packaging finishes are provided by eco-friendly options such as water-based varnishes and biodegradable laminates. These finishes reduce solvent emissions and lifecycle impact compared with traditional solvent-based coatings, supporting environmentally responsible packaging solutions.

Where are Packaging Finishes Used Across Different Industries?

Packaging finishes are applied across rigid boxes, folding cartons, flexible films, and labels, with preferences varying by industry. Cosmetics often use soft-touch coatings, foil stamping, and embossing; food packaging prioritises film lamination and barrier coatings; pharmaceuticals require durable, legible prints often protected with aqueous varnishes; electronics and consumer goods commonly use gloss lamination to enhance photographic imagery and scratch resistance.

Finishes for Beauty and Personal-Care Packaging

Finishes for beauty and personal-care packaging combine soft-touch coatings, metallic foils, and embossing to create tactile and visual cues of value. These finishes are chosen for ink adhesion on coated boards and durability under repeated handling, with spot finishes around brand marks and labels frequently applied for emphasis.

Finishes for Paperboard and Rigid Box

Paperboard and rigid box applications use aqueous varnish, lamination, spot ultraviolet, and foil stamping. Lamination affects fold scores and adhesive behaviour, which must be considered in die-line design. Embossing adds structural relief without the need for additional inks.

Finishes for Flexible Packaging

Flexible packaging relies on film lamination, metallised films, and specialised coatings to provide barrier properties and finish effects such as gloss, matte, and paper-touch textures. These finishes are applied during film extrusion or web lamination and influence seal integrity and printability.

Finishes for Holographic Foils

Holographic foils and diffractive films are used for anti-counterfeiting or high-impact visual effects. They can be incorporated as lamination layers or applied selectively via stamping, with precise registration and die accuracy essential to maintain visual fidelity.

What Sustainability Considerations Affect Packaging Finishes?

Sustainability considerations in packaging finishes focus on reducing environmental impact while maintaining performance. Water-based varnishes lower volatile organic compound emissions compared with solvent-based coatings. Biodegradable laminates and recyclable mono-material films minimise end-of-life impact when aligned with local recycling systems. In contrast, multilayer laminates and mixed-material foils complicate recycling, making recyclable or mono-material finishing systems preferable when mechanical recycling is needed. Balancing eco-friendliness with barrier performance and cost is key to sustainable finish selection.

How are Packaging Finishes Combined and Applied?

Packaging finishes are chosen based on design goals, substrate compatibility, print method, cost, and performance needs. Common combinations include a matte base with spot ultraviolet highlights or foil stamping paired with embossing. The process follows a practical sequence: printing, varnish or lacquer application, lamination if required, foil stamping or embossing, die-cutting, and folding and glueing. Application methods of packaging finishes vary by finish, including roller coating, web lamination, ultraviolet curing, and hot-foil stamping. Proper selection, combination, and sequencing ensure visually appealing, durable, and high-quality packaging.

What Practical Constraints Affect Packaging Finishes?

Selection of packaging finishes is influenced by several practical constraints that affect cost, timing, and production efficiency. Key constraints include:

- Cost: Tooling-based finishes have high upfront and per-unit costs; digital finishes reduce setup but increase material expenses. Each added finish raises the overall cost.

- Lead Time: Die creation and press setup for tooling-based finishes extend production schedules; digital methods offer faster turnaround for short runs.

- Scalability: Multiple finishes increase converting steps, require precise registration, and can affect yield; some methods suit short runs, others large-scale production.

What are the Key Factors and Quality Checks for Selecting Packaging Finishes?

Key factors for selecting packaging finishes include the substrate, such as paperboard, rigid board, or polymer film, and the printing method, like offset, flexographic, or digital, which affects adhesion and registration. The distribution environment, including refrigerated, humid, or high-abrasion handling, also influences finish choice. Regulatory requirements, such as direct food contact or pharmaceutical labelling, must be met, and budget and run length determine whether digital finishes or traditional tooling are more suitable. Quality verification involves assessing finished samples for adhesion, rub resistance, gloss, and dimensional stability. Common tests include tape adhesion, rub tests for scuff resistance, glossmeter readings, visual inspection for colour shifts after lamination, and, when needed, water vapour or oxygen transmission tests for laminated flexible packaging.

What are the Current Trends in Packaging Finishes?

Packaging finish trends reflect a focus on sustainability, visual differentiation, and flexible production methods. Key trends include:

- Increased use of lower-impact chemistries, such as water-based varnishes and compostable films, for sustainability.

- Selective combinations of finishes, like matte backgrounds with gloss accents, holographic elements, or soft-touch areas, to create tactile contrast and shelf appeal.

- Expanded adoption of digital finishing techniques for short runs and customised designs.

- Focus on targeted material use to balance visual impact with environmental responsibility.