UV coating is a clear, UV‑curable liquid applied to printed packaging substrates that polymerises under ultraviolet radiation to form a hard, protective film. The process runs from print preparation, substrate checks and liquid application through rapid curing and fold control, and manufacturers use flood, spot, raised, soft‑touch, textured or coloured films on cartons, labels or sleeves. Benefits of UV coating group into optical strength, abrasion control, moisture resistance, rapid curing, tactile variation and production consistency across folding cartons, rigid boxes and mailers, so packaging keeps colour density and readable text during handling. The uses of UV coating concentrate on surface protection, visual emphasis, moisture and smear control, transit durability and chemical‑contact stability on UK consumer goods.

- What is UV Coating in Packaging?

- What is the Process of Coating in Packaging?

- 1. Print stage

- 2. Substrate check

- 3. Coating Application

- 4. UV Curing

- 5. Post‑cure Handling

- 6. Fold control

- What are the Types of UV Coating Used in Packaging?

- Flood UV Coating

- Spot UV Coating

- Raised UV Coating

- Soft‑Touch UV

- Textured UV

- High‑Gloss UV

- Matte UV

- Pearlescent and Glitter UV

- Coloured UV

- What are the Benefits of UV Coating in Packaging?

- Optical Strength and Colour Density

- Abrasion and Scratch Control

- Moisture and Smear Resistance

- Rapid Curing and Production Throughput

- Visual and Tactile Variation

- Surface Stability During Transit

- Chemical‑Contact Tolerance

- Sustainability and Material Performance

- Safety and Regulatory Behaviour

- What are the Uses of UV Coating in Packaging?

What is UV Coating in Packaging?

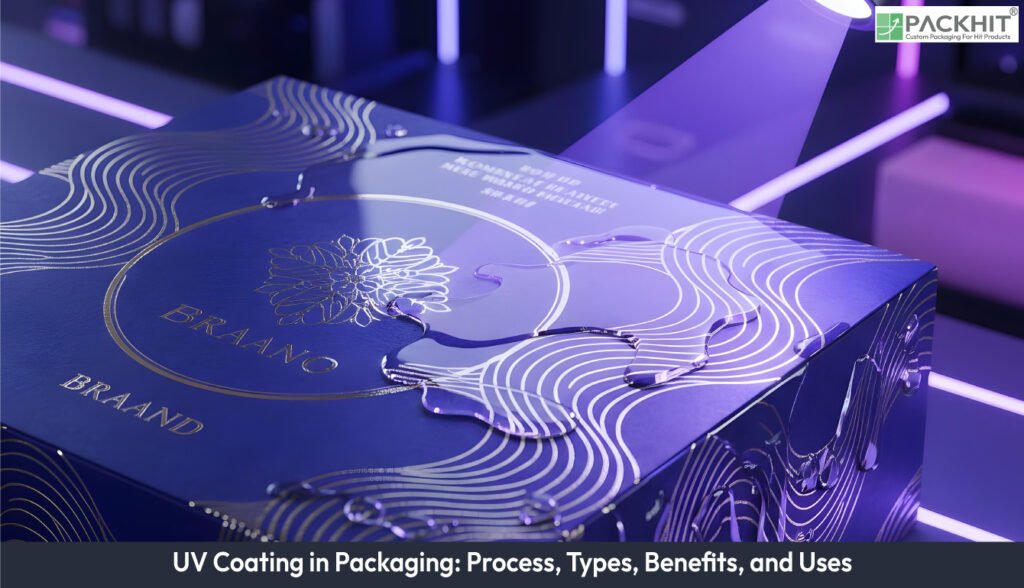

UV coating is a post‑print surface finish consisting of a clear liquid that is cured by ultraviolet light to form a hard film on packaging surfaces. As a specification, it is a coating type whose material base is UV‑curable chemistry, and whose primary functions are to provide abrasion and scratch resistance and to modify optical properties such as gloss and colour saturation.

What are the Properties of UV Coating?

The properties of UV coating are as follows:

- Gloss level: high‑gloss, satin and matte grades on folding cartons and labels.

- Tactile profile: soft‑touch and textured variants on garment tags and grip panels.

- Film thickness: thin, uniform layers that reduce scuffing on printed boards.

- Colour response: stronger saturation on dark graphics and sharper image edges.

- Moisture barrier: partial water resistance on bottle labels and mailers.

- Chemical resistance: tolerance to detergents and oils on household‑product labels.

- Surface clarity: smooth films that hold detail on photographic panels.

- Operational stability: consistent curing across gloss and matte grades cited in classification lists.

What is the Process of Coating in Packaging?

The process has six main stages that explain how UV coating works on printed packaging. Each stage is explained below:

1. Print stage

Print stage places artwork on the substrate with offset or compatible digital presses and sets ink density before coating. Ink films air out to release trapped volatiles, and sheet stability increases on coated papers. According to process notes cited in early UV‑coating classifications, ink films cure more consistently when the printed layer exposes minimal solvent content before any UV liquid contacts the sheet.

2. Substrate check

Substrate check confirms porosity and surface‑tension values that match the selected coating grade. Coated board, textured board or treated plastics receive sample tests that check wet‑film holdout and adhesion. Technicians inspect two to three sheets to confirm that the coating deposits an even film and avoids repellent patterns, if any surface additives remain on the stock.

3. Coating Application

Coating application deposits UV liquid with roller, blanket or screen systems. Roller heads apply uniform flood films, and screens define selective regions such as logos or title blocks. Classification references list gloss and matte UV as common grades, and the same application logic applies to either category. Viscosity checks control film weight and avoid pooling around dense artwork zones.

4. UV Curing

UV curing passes the wet film under mercury or LED lamps, where photoinitiators produce cross‑links within seconds. The reaction locks the film and eliminates solvent venting. LED sources emit narrow spectra and reduce ozone output, and mercury lamps support higher lamp intensity for thicker deposits, if raised films are required.

5. Post‑cure Handling

Post‑cure handling moves hardened sheets to cutting, folding and glueing. Glue flaps, label panels or writable areas remain uncoated because the polymeric film resists adhesive bonding and ink marking. The cured layer prevents smearing during stacking and transit to finishing stations if sheets pass through automated feeders.

6. Fold control

Fold control marks fold points with raster or white lines to limit cracking on tight bends. Heavier boards stiffen after curing, and surface breaks appear if bends force the cross‑linked network to fracture. Sample sheets often confirm fold performance before full‑run production, especially when cartons use narrow gussets or multiple crease lines.

This sequence aligns with process categories described in technical guides on UV coating, where spot, flood and textured films follow a similar curing logic.t.

What are the Types of UV Coating Used in Packaging?

The types of UV coating used in packaging are given below:

Flood UV Coating

Flood UV coating creates a continuous film across the sheet and keeps reflectance stable on printed panels. The film raises colour density, adds abrasion control, and protects fibres during transport. Rigid boxes, subscription mailers and folding cartons use this method on wrap‑around artwork zones.

Spot UV Coating

Spot UV coating restricts the cured layer to selected graphics. Logos, titles and photographic blocks gain higher contrast because the clear varnish alters local reflectance. Prepress files carry a separate mask layer that registers the coated regions. Thin lines, geometric patterns and icon sets in retail packaging use this process on brand marks or colour bars.

Raised UV Coating

Raised UV coating builds height by stacking two or three passes of screen‑printed varnish. Each pass cures before the next to stop the wet film from spreading. This approach produces tactile identifiers on product cartons, fragrance boxes or booklet covers. The height increases grip on hand‑held pieces and defines Braille‑like cues in accessibility formats.

Soft‑Touch UV

Soft‑touch UV uses altered oligomer and filler ratios that reduce surface friction after curing. The finish mutes glare and gives a low‑sheen surface. Garment tags, limited‑run sleeves and presentation cartons apply this variant when light scatter needs stronger suppression than matte gloss grades listed in older classification notes.

Textured UV

Textured UV relies on particulate additives or patterned screens that interrupt the wet film before curing. The process forms micro‑relief patterns used on grip panels, anti‑slip flaps and decorative borders on gift packaging. The effect stays within the same curing window as standard gloss coatings if viscosity checks match the screen density.

High‑Gloss UV

High‑gloss UV uses clear films that form a smooth surface with strong specular reflection. This grade raises colour strength on electronics cartons, premium sleeves and POS cards. Gloss UV sits in the highest optical‑intensity group in common classifications, and sheets cure within seconds under mercury or LED lamps.

Matte UV

Matte UV lowers reflectance across the sheet. The finish supports text‑heavy layouts, photographic covers and subdued brand palettes. Its curing behaviour matches gloss variants, although some fillers adjust film diffusion. Packaging for books, stationery and batch‑coded inserts uses this grade on reading surfaces.

Pearlescent and Glitter UV

Pearlescent UV scatters incident light through plate‑like pigments, and glitter UV uses larger reflective particles that add point flashes. Gift boxes, seasonal cartons and promotional sleeves apply these effects along borders or title panels. Both coatings require compatibility checks so pigment orientation stays stable during the UV cycle.

Coloured UV

Coloured UV adds tinted varnish over printed regions. The film shifts hue without obscuring underlying graphics. Labels, drink sleeves, and promo cards use narrow bands of tinted varnish to define gradients or warn‑label outlines. Wet‑film density controls colour strength if the substrate has low porosity.

What are the Benefits of UV Coating in Packaging?

UV coating adds surface hardness, scratch control, gloss strength and colour density, and the cured film forms within seconds. The cured layer limits fingerprint marks and slows colour shift under lighting. These traits support packaging that moves through retail fixtures, postal equipment or hand‑held use.

Optical Strength and Colour Density

UV films raise reflectance on printed panels and make saturated colours appear deeper. Gloss variants produce a bright surface on folding cartons and labels; matte variants cut glare on reading zones such as inserts or book‑related packaging. Spot coats isolate logos or title blocks if local contrast needs a tighter focal point.

Abrasion and Scratch Control

The cured network resists abrasion from conveyors, shelf contact and handling, and printed fibres stay stable when boards run through postal rollers or store fixtures. Gloss UV produces the hardest surface among common liquid UV grades on paperboard, and this hardness limits scratch marks during transit or repeated stacking.

Moisture and Smear Resistance

The polymerised film slows moisture ingress and keeps the ink stable during contact with liquids. Labels on bottles and household‑product packs retain legibility after splash contact. Printed zones do not smear during die‑cutting or case forming if the coating excludes glue flaps.

Rapid Curing and Production Throughput

UV chemistry cures by photoinitiation rather than solvent venting, so sheets exit the curing unit ready for stacking, trimming or folding. Faster drying reduces staging time between printing and finishing. LED modules emit a narrow band that keeps curing consistently across short or long runs.

Visual and Tactile Variation

Multiple UV classes, such as gloss, matte, soft‑touch, textured, pearlescent and glitter, give print teams a defined set of optical or tactile changes. Soft‑touch cuts surface friction and suits garment tags or presentation cartons. Textured coatings provide micro‑relief for grip panels or decorative borders.

Surface Stability During Transit

Cartons, mailers and postcards coated with a continuous film keep ink stable during transport. Conveyor edges and automated feeders do not scrape printed zones as easily. Address data remains clear after incidental moisture exposure.

Chemical‑Contact Tolerance

UV films resist mild detergents, oils and solvents referenced in early coating classifications. Labels for cleaning liquids or cosmetics maintain printed density after repeated contact cycles. Colour shift stays limited because the cross‑linked layer restricts swelling.

Sustainability and Material Performance

Newer low‑VOC or solvent‑free UV grades reduce emissions. LED‑UV curing cuts ozone output and removes mercury disposal associated with older lamps. Paperboard coated with thin UV films passes through many recycling streams if mills accept polymeric residues.

Safety and Regulatory Behaviour

UV curing units operate with shielding and extraction that limit exposure to UV radiation. Operators use PPE during the handling of uncured liquid. Waste classification for lamps and leftover coating aligns with emissions controls defined for print plants in the UK.

What are the Uses of UV Coating in Packaging?

UV coating adds a cured film that protects printed boards, increases colour density and maintains readable text during repeated handling. It supports folding cartons, rigid boxes, labels and mailers such as perfume cartons, device boxes, bottle labels and corrugated mailers. The coating responds well where scuffing, high‑contact shelf storage or conveyor abrasion.

Surface Protection

UV coating protects fibre surfaces on printed boards by forming a hard, cross‑linked layer. This layer reduces the fibre lift seen on cosmetics cartons and gift boxes. Flood films prevent surface marking in stockrooms or retail fixtures and stabilise colour under direct lighting.

Visual Emphasis

Spot and raised UV highlight discrete artwork regions by adding gloss or height to targeted graphics. Spot layers isolate logos or photographic panels. Gloss films strengthen colour density on saturated graphics, while matte films control glare on reading zones. Raised deposits create tactile marks that separate brand identifiers or icons.

Moisture and Smear Control

UV coating restricts ink smear and slows moisture damage during handling. Liquids bead on the polymer network, so printed labels on bottles or cleaning‑product packs remain legible in kitchens or bathrooms. The cured layer prevents smearing during carton packing and case forming.

Transit and Postal Durability

UV coating stabilises printed surfaces that pass through postal and logistics equipment. E‑commerce mailers and postcards use full‑surface films so roller tracks or conveyor edges do not strip ink. Address data remains readable after short moisture exposure.

Hand‑held Print

UV coating reduces fingerprint marking and abrasion on hand‑held prints. Business cards, catalogue covers and trade‑show cards use spot or flood films to keep contrast stable. Raised UV adds grip on small formats where matte inks rub away.

Chemical‑Contact

UV coating preserves colour on labels that meet detergents, oils or mild solvents. Household‑liquid and cosmetic labels retain printed density because the cured network resists chemical swelling, a behaviour described in early UV‑coating classifications.