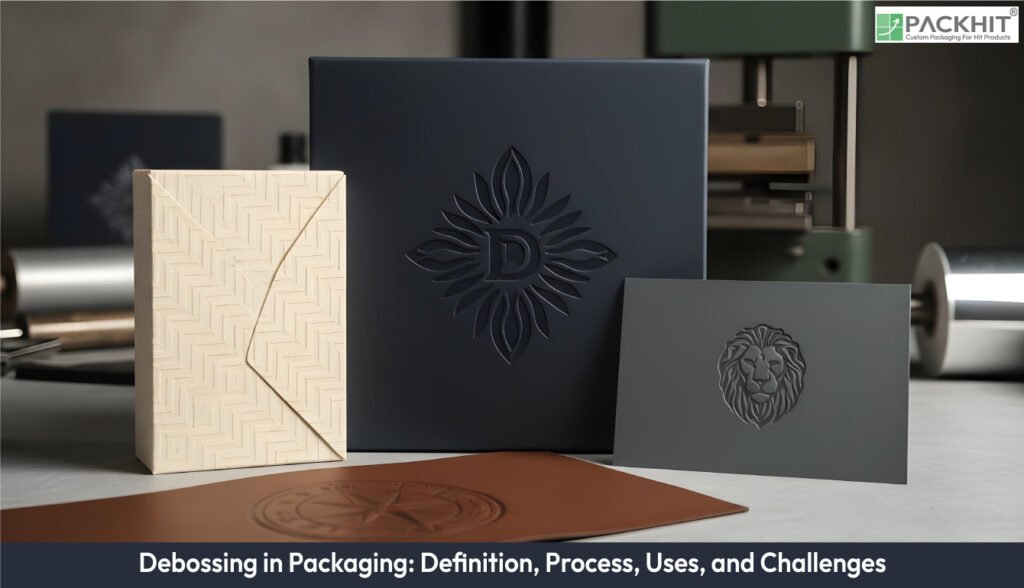

Debossing is a printing technique that creates recessed impressions on packaging surfaces, adding texture and visual interest without using ink or foil. The process of debossing in packaging involves pressing a die into the substrate under controlled pressure, which is applied to paper, cardboard, or speciality materials. Debossing enhances brand presentation by giving tactile cues, elevating perceived value, and highlighting logos, patterns, or text. Common uses of debossing in packaging include luxury product packaging, labels, invitations, and premium folding cartons. Challenges in debossing include selecting compatible substrates, managing die pressure to avoid damage, ensuring consistent depth across batches, and coordinating with other finishes to maintain registration and overall visual appeal.

- What is Debossing in Packaging?

- What is the Process of Debossing in Packaging?

- 1. Preparing Artwork and Dielines

- 2. Manufacturing the Debossing Die

- 3. Setting Press Parameters

- 4. Selecting Suitable Materials

- 5. Executing the Debossing Operation

- 6. Applying Secondary Finishes

- What are the Uses of Debossing in Packaging Across Different Sectors?

- Luxury Product Packaging

- Corporate and Promotional Materials

- Custom Retail Packaging

- Food and Beverage Packaging

- Tech and Electronics Packaging

- Wedding and Event Invitations

- Board Games, Leather Goods, and Stationery

- What are the Challenges of Debossing in Packaging?

- Costly Tooling and Run-Length

- Restrictive Material and Heat

- Complex Colour and Registration

- Sensitive Mechanical and Quality Control

- Sustainability Drawbacks

- What are the Differences Between Debossing and Embossing in Packaging?

What is Debossing in Packaging?

Debossing in packaging refers to a mechanical finishing process that presses a design into the surface to create a recessed impression. Debossing produces a concave texture that adds tactile depth and subtle light and shadow contrast without relying on added colour. The process uses custom dies to displace the material inward, forming a three-dimensional, indented effect. Ink application remains optional, which reduces ink usage and supports minimalist design goals. Common applications include paperboard and cardboard packaging, such as folding cartons and premium stationery, with selective use on leather and certain metals. Debossing supports brand differentiation and refined presentation where understated visual impact and tactile quality are required.

What is the Process of Debossing in Packaging?

The debossing process follows a clear, step-by-step workflow that moves from design preparation to final finishing while controlling depth, alignment, and material response.

1. Preparing Artwork and Dielines

Prepare artwork and dielines to define the recessed design and placement on the package. Vector files specify depth, edge detail, and alignment requirements to ensure the debossed area matches design intent.

2. Manufacturing the Debossing Die

Manufacture the debossing die to create the negative form of the artwork. A custom metal die is produced as a single female die or as a matched die set for multi-level impressions and tighter registration.

3. Setting Press Parameters

Set press parameters to control impression quality and repeatability. Pressure applies the force needed to displace material, heat softens fibres or coatings when required, and dwell time determines how long force and heat act on the substrate.

4. Selecting Suitable Materials

Select suitable materials to achieve the intended depth and definition. Thin stocks support shallow impressions, while heavier paperboard allows deeper or sculptured debossing without structural damage.

5. Executing the Debossing Operation

Execute the debossing operation using manual tools for prototypes or machine presses for production runs. Controlled sheet-by-sheet processing ensures consistent depth and alignment at scale.

6. Applying Secondary Finishes

Apply secondary finishes if needed to enhance visual impact. Foil stamping or screen printing can be added within or around debossed areas, with additional passes increasing alignment demands and production cost.

What are the Uses of Debossing in Packaging Across Different Sectors?

Debossing in packaging enhances brand identity, tactile appeal, and visual interest across a wide range of packaging and product categories. Debossing adapts to each sector’s unique needs, highlighting luxury, reinforcing corporate identity, enhancing tactile engagement, or improving product differentiation, and making it a versatile and widely used finishing technique.

Luxury Product Packaging

Luxury product packaging uses debossing to create a refined, premium feel. Recessed logos, monograms, and design elements on perfume boxes, jewellery packaging, and high-end cosmetics provide tactile engagement, communicate exclusivity, and elevate shelf presence for discerning consumers.

Corporate and Promotional Materials

Corporate and promotional packaging applies debossing to gift boxes, business card holders, and branded kits. Recessed logos and designs add sophistication, enhance unboxing experiences, and subtly reinforce corporate identity and professionalism.

Custom Retail Packaging

Custom retail packaging leverages debossing for limited-edition items, gift sets, and seasonal products. Recessed elements differentiate products from competitors, draw consumer attention, and strengthen brand recognition through tactile cues.

Food and Beverage Packaging

Food and beverage packaging incorporates debossing on premium chocolates, wine boxes, spirits cases, and speciality food boxes. Recessed logos or patterns communicate craftsmanship, enhance tactile interaction, and visually signal artisanal or luxury quality.

Tech and Electronics Packaging

Technology and electronics packaging use debossing on smartphone boxes, high-end gadget cases, and accessory packaging. Recessed logos and surface patterns provide tactile and visual quality cues while reinforcing brand identity and a sense of sophistication.

Wedding and Event Invitations

Wedding and event stationery applies debossing to invitations, greeting cards, and event programs. Recessed monograms or patterns create elegant tactile effects, convey sophistication, and offer recipients a memorable, premium keepsake.

Board Games, Leather Goods, and Stationery

Board and card game boxes, leather wallets and journals, and stationery products like business cards use debossing to add tactile richness, durable branding, and visual appeal. Shallow or spot debossing increases interaction and enhances perceived value across these sectors.

What are the Challenges of Debossing in Packaging?

Debossing in packaging has several challenges that impact cost, material choice, production complexity, and quality control.

Costly Tooling and Run-Length

Costly tooling and run-length requirements increase setup expenses and make small-volume runs uneconomical. Custom dies are needed for detailed impressions, and extra steps for colour or foil registration raise the per-unit cost. Labour remains sheet-by-sheet, limiting operational efficiency.

Restrictive Material and Heat

Restrictive material and heat requirements limit substrate options. High heat is needed for deep impressions, damaging plastics or fabrics. Thin materials risk tearing or warping, making heavier paperboard necessary for multi-level designs.

Complex Colour and Registration

Complex colour and registration requirements increase finishing difficulty. Applying ink within recesses demands precise alignment, and combining debossing with foil stamping or screen printing produces visible defects if misregistration occurs.

Sensitive Mechanical and Quality Control

Sensitive mechanical and quality control tolerances affect consistency. Uneven pressure, worn dies, poor alignment, or inconsistent sheet dimensions result in uneven impressions or backside distortion on thin substrates.

Sustainability Drawbacks

Debossing reduces ink usage when applied as a blind finish, lowering solvent and pigment consumption compared with high‑ink processes. The technique’s overall environmental footprint is commonly small relative to heavily inked processes, but die manufacture and energy used in heated presses contribute to upstream impacts and should be considered in lifecycle assessments.

What are the Differences Between Debossing and Embossing in Packaging?

Debossing and embossing represent two primary mechanical finishing techniques that create tactile effects by sinking or raising artwork on packaging surfaces. The table below highlights key differences between the two methods, helping guide the choice of technique for specific packaging applications.

| Feature | Debossing | Embossing |

|---|---|---|

| Design Effect | Sinks artwork below the surface (concave) | Raises artwork above the surface (convex) |

| Visual Impact | Subtle, minimalist, tactile | Highly visible, catches light and shadow |

| Brand Signaling | Subdued, elegant, tactile | Bold, prominent, attention-grabbing |

| Heat Requirement | Often requires higher heat | Typically lower heat than debossing |

| Tooling | Single or dual dies, depending on depth/registration | Single or dual dies, depending on depth/registration |

| Labour and Operation | Sheet-by-sheet, similar to embossing | Sheet-by-sheet, similar to debossing |

| Cost Consideration | Cheaper per unit for some setups | Comparable per-unit cost, depends on die and run length |

| Best Use Case | Minimalist packaging, subtle branding, tactile logos | Packaging needing raised, prominent relief and high visibility |

Debossing offers subtle, recessed texture and tactile appeal, while embossing provides raised, highly visible relief. Choice depends on desired visual impact, brand messaging, material compatibility, and production considerations.