Corrugated flutes are the wavy paper arches between two liners that give corrugated board its strength, cushioning and print surface stability. They come in profiles such as A, C, B, E and F, each offering different balances of rigidity, impact absorption and printability. Thicker flutes increase cushioning and stacking strength, while thinner flutes improve surface flatness for high-quality graphics. Flute thickness directly affects board rigidity, how well the sheet absorbs shock and how smoothly it prints. Overall durability depends on material quality, environmental exposure, adhesive bonding, flute geometry and production accuracy, all of which influence crush resistance and long-term performance. Different industries choose flute types based on product weight, fragility and display needs. Heavy industrial goods use A or C flutes, retail packs favour E or F, and food packaging uses balanced profiles. Designers select flute types by matching weight, print needs, shipping conditions and budget, while quality is controlled through metrics such as compressive strength, ECT, cushioning performance, surface flatness and bond integrity to ensure consistent behaviour in transit.

- What are Corrugated Flutes?

- What are the Types of Corrugated Flutes?

- How Does Flute Thickness Affect Rigidity, Cushioning and Printability?

- What Factors Determine the Durability of Corrugated Flutes?

- Where are Different Flute Types Applied Across Industries?

- How is a Flute Type Chosen During Packaging Design?

- What Metrics and Quality Controls Govern Flute Performance?

What are Corrugated Flutes?

Corrugated flutes form arched ridges and grooves in a fluted paper web that sits between two flat liner boards. These wavy arches create a structural core made from a shaped paper medium glued to the liners. The core absorbs compression, stacking load and impact while keeping the outer surfaces stable for printing. The flutes sit in the centre layer of corrugated board, often described as the “wavy part in the middle,” and this shaped layer controls how the board reacts to force during handling and transit.

Flutes carry three mechanical roles: adding cushioning against shock loads, supporting vertical stacking loads, and adding bending stiffness that keeps the board flat. Thicker profiles push cushioning higher and reduce surface smoothness. Finer profiles cut flute height and help the outer liners stay smooth for printing. The shaped medium creates these effects because the arches deform predictably under pressure. If flute height changes, stiffness, cushioning and print quality shift with it.

What are the Types of Corrugated Flutes?

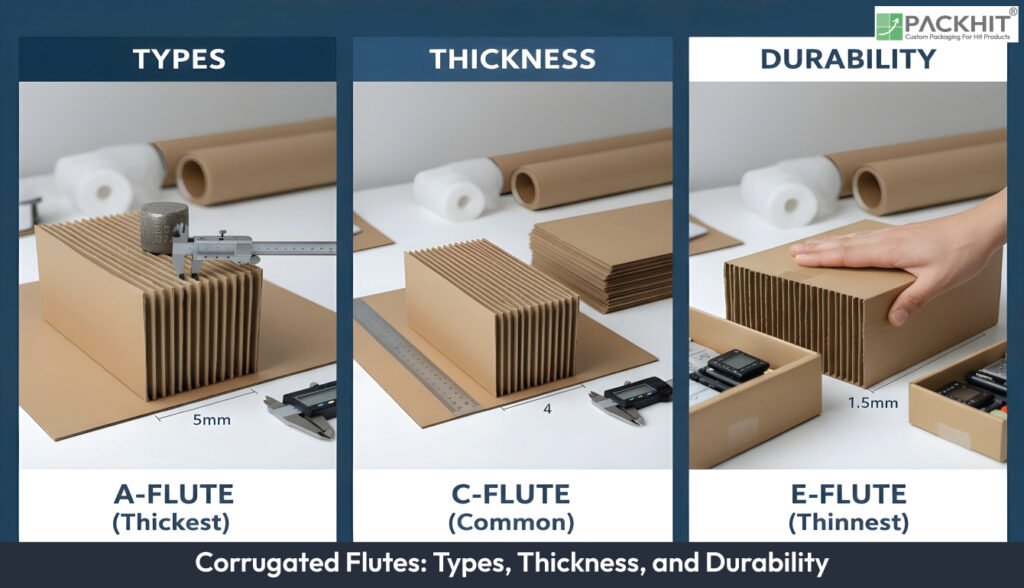

Five flute profiles are used across single‑wall corrugated boards: A, B, C, E and F. These profiles describe the height and spacing of the wavy fibre layer that sits between two liner boards. Each profile changes cushioning, stacking load behaviour and print surface flatness.

1. A Flute

A flute gives the thickest arch structure. The tall profile forms wide paper arches that spread compression and absorb impact. This profile supports bulky packs and transit loads for furniture, appliances or wholesale units. The wider arches supply more air volume and resist crushing during stacking.

2. C Flute

C flute gives mixed cushioning and stacking strength. The profile sits below A in height but holds enough arch depth for rigid boxes. Manufacturers use it for shipping cartons that carry medium‑weight products, if the board must keep a defined shape through long storage periods.

3. B Flute

B flute gives a tighter arch spacing. The reduced pitch improves flatness, so outer liners sit more evenly. This profile supports mechanical parts, retail multipacks or food trays where boards carry racking loads but also print fine graphics.

4. E Flute

E flute gives a thin, compact layer. The low height creates a stiff sheet with smoother liners. Print coverage improves if boxes show branding or barcodes. This profile fits die‑cut cartons, smaller retail packs and shelf‑ready boxes that need sharp creases.

5. F Flute

F flute or microflute gives the finest pitch. The narrow spacing supports micro‑flute formats for premium graphics and precise folds. This profile reduces total board thickness by large margins and suits smaller consumer packs or compact inner cartons.

Comparative observation: thicker profiles create more cushioning and absorb higher compressive loads; thinner profiles create flatter surfaces that print cleanly. Flute choice, therefore, changes weight, crush resistance and graphic performance in a predictable pattern.

How Does Flute Thickness Affect Rigidity, Cushioning and Printability?

Here is how flute thickness affects rigidity, cushioning and printability:

Board rigidity

Flute thickness sets total board thickness and bending stiffness. Thicker flutes form taller arches that hold compressive load and keep liners straighter during stacking. The shaped arches spread force across the liners and reduce panel deflection in transit.

Cushioning behaviour

Flute thickness controls cushioning because taller arches deform over a longer span. Thick profiles absorb impact energy from drops and vibration if products weigh more or carry brittle parts. The wavy medium inside the board flexes before the liners crease, so shock load transfer drops.

Printability

Flute thickness changes printability because thinner flutes reduce height variation across the sheet. A thin profile holds the liner flatter, so ink laydown stays even on small retail packs. Thin profiles also improve crease accuracy for die-cut cartons with tight fold geometry.

What Factors Determine the Durability of Corrugated Flutes?

Durability of corrugated flutes depends on five mechanical and environmental drivers. Each driver alters how the fluted medium, liners and adhesive behave under load, humidity and handling. These drivers interact; one weak link distorts stacking strength or crush resistance.

Material quality

Material quality shapes tear strength, burst resistance and stiffness retention across repeated compression cycles. Fibre composition in the fluted medium and liners, such as kraft–recycled blends used by packaging manufacturers in the UK, alters how the arches resist buckling if humidity rises in storage. The two-layer boards and the shaped medium form a three‑layer system that gains strength only if the fibres keep their bonded structure during transport.

Environmental exposure

Environmental exposure softens fibres, disrupts adhesive bonds and accelerates creep during long stacking periods. Humidity, temperature shifts and liquid contact flatten flute arches and degrade the glue line at flute peaks. A corrugated board that absorbs moisture loses stiffness across the centre layer first because the wavy medium carries the highest surface area.

Adhesive bonding

Adhesive bonding controls shear transfer between flute peaks and the liner boards. Bond coverage, glue type and nip pressure determine whether the fluted medium stays fixed under edge crush loads. A weak bond creates early delamination if panels face vibration or sustained vertical load during pallet transit.

Flute profile

Flute profile governs compression pathways and local stress points that occur in thick or thin arches. A and C profiles hold taller structures that resist crush in bulky packs, while E and F profiles bring compact spacing that flattens print surfaces but reduces deformation tolerance if impact loads rise. The height and pitch of the arches change how the middle layer reacts under load.

Production accuracy

Production accuracy sets flute pitch regularity, glue distribution and liner alignment. Variations in pitch alter total board thickness and distort bending performance, if flutes drift out of tolerance. Glue application errors create isolated weak points that reduce crush strength, while misaligned liners introduce warp that misbehaves during printing or stacking.

Durability failures concentrate at interfaces. A board made from high‑grade fibres but bonded with low glue weight often fails at the liner–flute joint; conversely, precise corrugator control maintains stiffness even if the medium uses higher recycled content in controlled warehouse environments.

Where are Different Flute Types Applied Across Industries?

Different flute profiles support industrial, retail and food sectors. These sectors use the wavy fibre layer inside corrugated board to match load, print and hygiene demands. The shaped arches in each profile change strength and surface flatness in predictable ways.

The different flute types that are used across industries are listed below

- Industrial packaging uses thick profiles (A, C) for bulk shipping and heavy machinery. The tall arches carry compression and keep liners stable if long stacking periods occur.

- Retail packaging uses thin profiles (E, F) for point‑of‑sale boxes and product displays. The compact pitch keeps the print surface flat and improves crease accuracy.

- Food packaging uses balanced profiles for primary overwrap boxes and takeaway containers. These packs rely on hygiene‑compatible liners and enough stiffness for short transport cycles.

Cross‑sector use links to logistics efficiency, recycling streams and shelf layout. The same wavy medium that forms the structural core in all board shapes strength, print quality and pack weight, so flute choice affects packaging performance across multiple supply chains.

How is a Flute Type Chosen During Packaging Design?

The flute type is chosen by matching product weight, graphics demand, transport conditions and cost, which is detailed below:

- Weight and fragility: use thicker flutes (A, C) for heavy or brittle items, if cushioning and crush strength dominate.

- Print and retail display: use thinner flutes (E, F) for smooth print and clean folds on retail cartons.

- Shipping conditions: use higher‑rigidity profiles for long stacking periods; use balanced profiles (B) for mixed loads.

- Budget constraints: match liner grade and flute geometry; a thin flute with stronger liners keeps print quality without extra board thickness.

The packaging team makes one combined decision. It reviews mechanical tests, cost targets and branding needs, then specifies flute profile, liner grade and adhesive type. Flute arches act as the structural core between the liner boards if the team keeps bond strength and geometry consistent.

What Metrics and Quality Controls Govern Flute Performance?

The key metrics that govern flute performance include compressive strength, edge crush resistance, cushioning capacity, surface flatness and bond integrity. These metrics track how the wavy fibre layer resists load and deformation because the curved arches in the fluted medium deform along predictable points of compression between the two liner boards. Laboratory checks record crush values, surface variation and bond behaviour across flute peaks that carry the adhesive. Dimensional checks confirm flute spacing, arch height and liner tension, if production runs long or humidity shifts during storage.