The Edge Crush Test and the Mullen Test are two fundamental methods for evaluating corrugated fibreboard performance, each measuring a different failure mechanism that directly affects packaging reliability. The Edge Crush Test focuses on edgewise compressive strength to predict how cartons perform under stacked pallet loads and vertical compression during warehousing and transport. The Mullen Test measures bursting strength to assess liner durability against puncture, point pressure, and outward forces caused by contents or handling impacts. Together, these tests explain how corrugated packaging behaves under compression versus rupture. There are certain pros and cons to each approach when selecting board grades for real-world distribution conditions.

What is the Edge Crush Test?

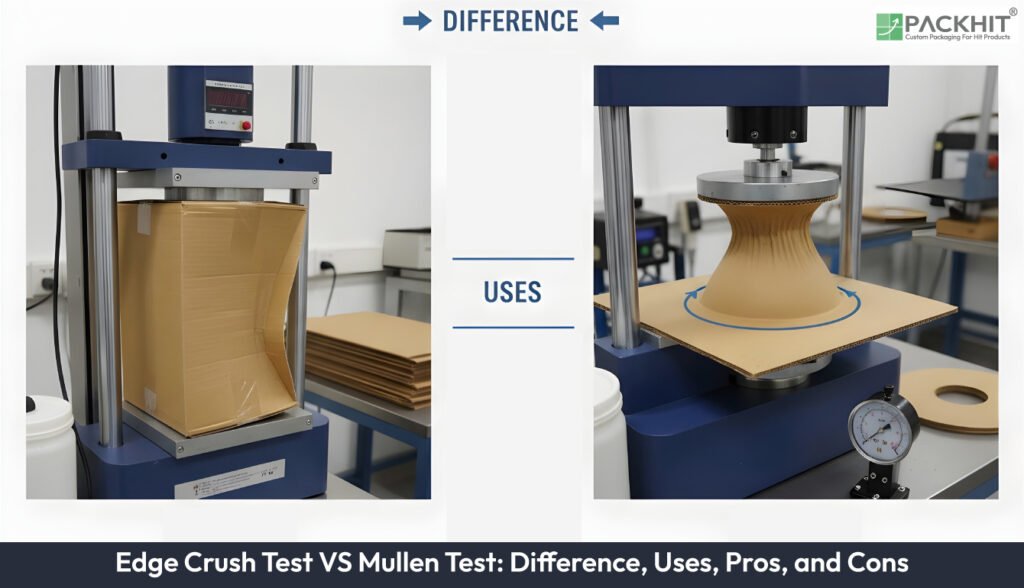

The edge crush test measures the edgewise compressive strength of corrugated fibreboard under a controlled load. The process compresses an hourglass-shaped specimen between two rigid platens until the material buckles. The recorded peak force per linear inch reflects how well a board resists top‑to‑bottom pressure in stacked conditions. The rating supports packaging choices for pallet loads that place stress on the vertical flute structure.

What is the Mullen Test?

The Mullen test measures the force needed to rupture the face of corrugated fibreboard under controlled hydraulic or pneumatic pressure. The test clamps a circular area of the board against a diaphragm, pressure rises until the liner breaks, and the peak value is recorded as a bursting‑strength number. The method assesses face durability against puncture loads from sharp edges or point pressure created by packed items. The result guides material selection for boxes exposed to direct impact or internal pressure rather than stacked compression.

How do the Edge Crush Test and the Mullen Test Differ?

The edge crush test and the Mullen test differ in load direction, specimen shape, measured failure mode, and reported strength units. These distinctions influence how engineers predict stacked compression or face rupture in UK transport networks. The table below outlines each technical difference so manufacturers can compare both procedures before choosing a board grade for pallet routes or courier parcels.

| Difference | Edge Crush Test (ECT) | Mullen Test (Burst) |

|---|---|---|

| Load direction | Applies a vertical load along the board edge as platen pressure travels through flute columns. | Applies hydraulic or pneumatic pressure outward across a clamped circular face. |

| Measured failure mode | Records buckling of flutes when the hourglass specimen collapses under edgewise compression. | Records rupture of liners when the diaphragm punctures the face during rising pressure. |

| Specimen geometry | Uses an hourglass strip cut perpendicular to the flutes to centralise compression. | Uses a flat board section clamped around a circular opening with a fixed test area. |

| Reported units | The state’s strength in pounds per lineal inch is because the load acts along the flute columns. | The state’s strength in pounds per square inch is because the load spreads across the diaphragm face. |

| Predicted condition | Predicts stacked pallet compression if vertical pressure dominates the load case. | Predicts puncture or outward pressure if point loads or surface impacts occur. |

| Relevant certificates | Links to ECT marks printed on UK boxes for stacked performance verification. | Links to bursting‑strength ratings used for export cartons or face‑impact conditions. |

This comparison shows why ECT grades align with column stability in warehouses, while Mullen ratings relate to rupture thresholds recorded during diaphragm testing. Manufacturers pick the test that matches the hazards their supply chain produces.

What are the Primary Uses of the Edge Crush Test and the Mullen Test?

The primary uses of the edge crush test and the Mullen test place each method within a clear load case so manufacturers match board grade to transport pressure.

- Predict stacked load behaviour in pallet warehouses, if cartons carry dense goods that compress flutes.

- Estimate box compression strength with McKee-type calculations for multi‑wall or single‑wall boards.

- Check vertical column stability across UK courier routes where pallets add top‑to‑bottom pressure.

- Assess face rupture limits when goods press outward or when parcels meet point impacts during handling.

- Verify bursting‑strength marks for export cartons that face variable impact loads in long‑distance transit.

- Support certificate stamping so buyers can confirm whether a box meets ECT or burst requirements before loading.

What are the Pros and Cons of the Edge Crush Test and the Mullen Test?

The pros and cons of the Edge Crush Test and the Mullen Test include how each method predicts real transport stress for UK packaging that faces stacked loads or impacts.

Pros of the Edge Crush Test (ECT)

- Predicts stacked compression strength for pallet loads that press through flute columns.

- Uses edgewise measurement that mirrors warehouse storage, where vertical pressure dominates.

- Supports McKee‑type compression calculations for single‑wall or multi‑wall boards.

- Links to printed ECT marks that indicate minimum edgewise strength for UK shipments.

Cons of the Edge Crush Test (ECT)

- Does not record face rupture when sharp items press outward against liners.

- Under‑represents damage risk during courier sorting, where point impacts occur.

- Provides limited insight for packages with internal pressure, for example, liquids or inflated goods.

Pros of the Mullen Test (Burst)

- Measures linear rupture strength under rising hydraulic or pneumatic pressure across a fixed test area.

- Captures puncture resistance when goods with corners or metal parts load the board face.

- Supports burst‑grade selection for export cartons that face shifting impact loads in long transit.

Cons of the Mullen Test (Burst)

- Does not reflect the stacked column strength that depends on flute geometry.

- Limits prediction accuracy for palletised loads where vertical compression dominates.

- Provides mixed guidance for warehouse storage if cartons remain under long‑term top pressure.